LATEST NEWS

48V battery production ramp-up highly critical: ILS stabilises output

The ramp-up of 48V battery production at automotive suppliers is highly critical. The current problems are manifold. Among other things, poor performance, process and supply issues lead to under-delivery to customers. ILS stabilises performance and value stream through professional management experience, expert knowledge and sustainable problem-solving competence...

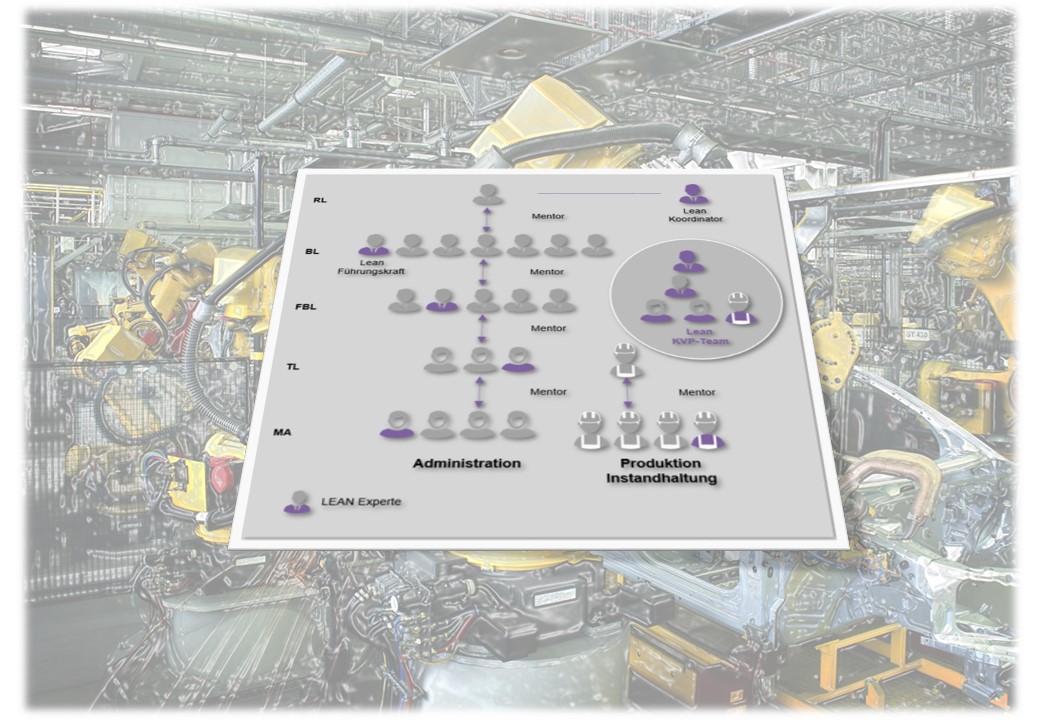

Cost-cutting initiative at a medium-sized company: Increasing efficiency in the organisation

ILS brings lean organisation to medium-sized companies! An organisational structure perfectly tailored to your goals. It all began with a thorough analysis of internal processes. Expanding responsibilities leads to success.

Factory planning: Near Helsinki

Fascinating factory planning project near Helsinki: To kick off the project, we carried out a quick review of the current production process in the factory. The existing database was checked for "value-adding" and "non-value-adding" parts. In addition, we analyzed the material flow of both prefabrication and the main lines in order to identify optimization opportunities. Our task is now to design a material flow that is optimally tailored to the customer's needs, focusing in particular on the layout of the workstations using lean management methods. The aim is to significantly reduce production costs and increase output.

Expansion: MIAS doubles production volume in Hungary

.webp)

Expansion: MIAS doubles production volume in Hungary

The Karlsruhe-based consultancy Integrated Logistics Systems (ILS) has taken on the role of general contractor for the overall planning of the production and logistics processes for the Hungarian site in Gyöngyös of the Munich-based Jungheinrich subsidiary Mias. As the company has announced, the plant located around 50 kilometers northeast of Budapest is considered the central production site for storage and retrieval machines (SRMs) for Europe and overseas...

ILS-MEDIA LIBRARY

DOWNLOADS

INTEGRATED LOGISTICS SYSTEMS

Postweg 51

D-76187 Karlsruhe

Germany

Tel: +49 721-97037-27

E-Mail: info@ilsystem.de

IT-Systems

ERP-Systems

We specialize in the implementation and design of ERP systems as well as the optimization of existing systems. Our experienced team works closely with your company to develop customized solutions that improve your business processes and increase your company's success.

Our approach begins with a thorough analysis of your requirements. We capture your business processes and identify potential weaknesses, inefficiencies and bottlenecks. Based on these findings, we develop a customized design for your ERP system that optimally fits your specific requirements.

Our approach begins with a thorough analysis of your requirements. We capture your business processes and identify potential weaknesses, inefficiencies and bottlenecks. Based on these findings, we develop a customized design for your ERP system that optimally fits your specific requirements.

Our goal is to optimize your processes and increase your operational efficiency. We use proven methodologies such as Lean Management and Six Sigma to reduce waste and improve the value stream. By carefully tailoring the ERP system to your needs, we maximize benefits and minimize complexity.

Migrating your data to the new system is an important step that we perform with great care. We check the data quality, clean up if necessary, and ensure that the data structure and integrity are preserved. This way, you can be sure that you have access to reliable data and can make informed decisions.

Our team places a high priority on training and change management. We ensure that your employees are familiar with the new ERP system and understand the new processes. Through training and support activities, we minimize resistance to change and ensure a smooth implementation.

After implementation, we continuously monitor the performance and effectiveness of the system. We strive to ensure your satisfaction and are always available for questions and support. Our goal is to build long-term partnerships and help you continually improve your ERP system to meet the changing needs of your business.

Contact us today to learn more about how ILS can help you implement, design and optimize your ERP system. Together we create a solid foundation for your business success