LATEST NEWS

48V battery production ramp-up highly critical: ILS stabilises output

The ramp-up of 48V battery production at automotive suppliers is highly critical. The current problems are manifold. Among other things, poor performance, process and supply issues lead to under-delivery to customers. ILS stabilises performance and value stream through professional management experience, expert knowledge and sustainable problem-solving competence...

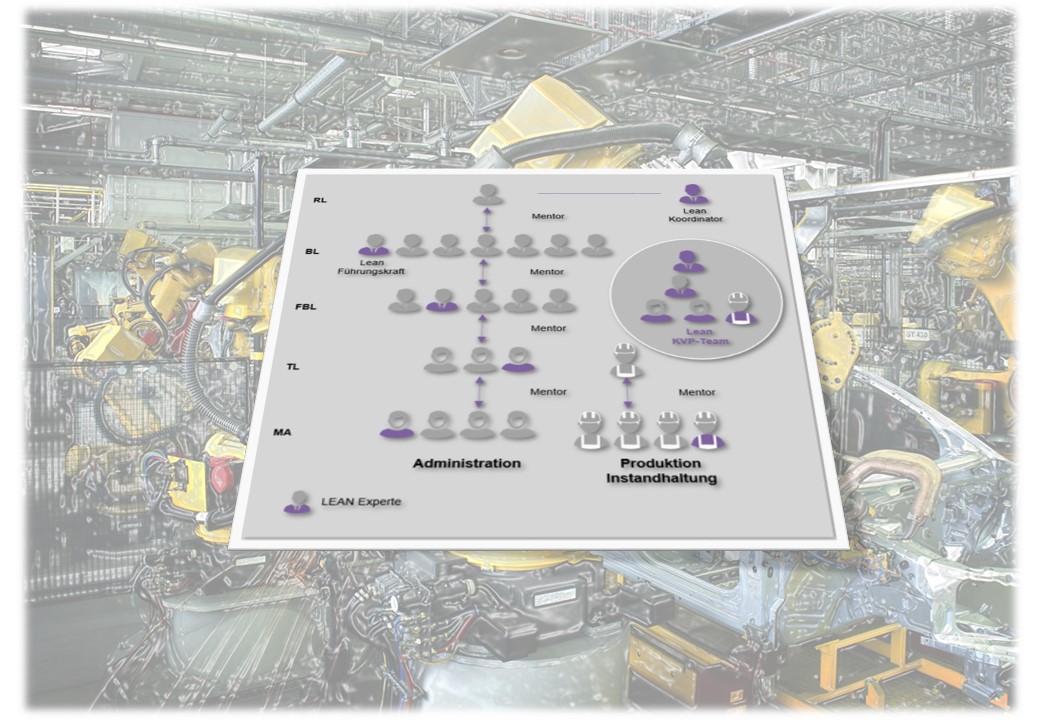

Cost-cutting initiative at a medium-sized company: Increasing efficiency in the organisation

ILS brings lean organisation to medium-sized companies! An organisational structure perfectly tailored to your goals. It all began with a thorough analysis of internal processes. Expanding responsibilities leads to success.

Factory planning: Near Helsinki

Fascinating factory planning project near Helsinki: To kick off the project, we carried out a quick review of the current production process in the factory. The existing database was checked for "value-adding" and "non-value-adding" parts. In addition, we analyzed the material flow of both prefabrication and the main lines in order to identify optimization opportunities. Our task is now to design a material flow that is optimally tailored to the customer's needs, focusing in particular on the layout of the workstations using lean management methods. The aim is to significantly reduce production costs and increase output.

Expansion: MIAS doubles production volume in Hungary

.webp)

Expansion: MIAS doubles production volume in Hungary

The Karlsruhe-based consultancy Integrated Logistics Systems (ILS) has taken on the role of general contractor for the overall planning of the production and logistics processes for the Hungarian site in Gyöngyös of the Munich-based Jungheinrich subsidiary Mias. As the company has announced, the plant located around 50 kilometers northeast of Budapest is considered the central production site for storage and retrieval machines (SRMs) for Europe and overseas...

ILS-MEDIA LIBRARY

DOWNLOADS

INTEGRATED LOGISTICS SYSTEMS

Postweg 51

D-76187 Karlsruhe

Germany

Tel: +49 721-97037-27

E-Mail: info@ilsystem.de

Logistics

Welcome to Integrated Logistics Systems - your partner for maximum cost efficiency along the supply chain

Logistics is a key cost factor in your company. Efficient logistics processes along the supply chain are crucial to your company's success.

Our focus is on lean and efficient processes, and we analyze, plan and implement efficient logistics structures for your company. In doing so, we are guided by the principles of lean management in order to make material and information flows sustainably efficient. The entire supply chain, from raw materials to the end customer, is consistently geared towards value creation.

Our services at a glance:

Our services at a glance:

Strategy in supply chain management: We support you in the planning and implementation of cross-location flows of goods and materials. Our analysis and optimization of your supplier structure as well as supplier evaluations and monitoring stabilize your supply chain in the long term.

Inventory management: Our experienced consultants evaluate your current inventories based on a standardized analysis of your order situation and sales expectations. We develop and implement inventory controlling concepts to determine the optimal solutions for you.

Spare parts strategy: Smoothly functioning spare parts logistics is the key to satisfied customers. We develop an economical and punctual spare parts strategy for you with a focus on the long term and cost-effectiveness.

Key figure systems: We analyze your existing key performance indicator system, identify weaknesses and support you in developing and implementing a powerful system that is tailored to your individual needs.

Site selection: After analyzing your business model and business cases, we jointly define the framework conditions for site selection. Our international network enables us to evaluate locations worldwide based on your specifications and long-term utilization concepts.

Material flow optimization: Lean processes mean lower costs. We analyze your logistics parameters and develop and implement lean processes for you according to lean principles.

Material flow planning: Our expertise covers all process steps in material flow planning, from traileryard to dispatch. We develop forward-looking layouts with a high degree of flexibility and rely on standardized simulations for validation.

Standard delivery forms: We identify part families for standard delivery forms and plan the process steps in detail. We define and implement control instruments for synchronized delivery in the customer cycle.

Pre-series process / supplier development: Our professional start-up and change management support includes maturity level checks, monitoring of delivery quality and employee training for a smooth pre-series process.

Holistic planning approach: Our economic approach to business processes is always holistic in order to avoid isolated solutions and determine the actual total costs.

Warehouse planning: The right warehouse technology is crucial. We determine the appropriate technology and picking strategies for your requirements, including bottleneck checks and ensuring the defined dynamics.

At Integrated Logistics Systems, experienced consultants will guide you towards lean and efficient logistics processes that increase your business success. Contact us today to learn more about our services and how we can optimize your supply chain.