LATEST NEWS

48V battery production ramp-up highly critical: ILS stabilises output

The ramp-up of 48V battery production at automotive suppliers is highly critical. The current problems are manifold. Among other things, poor performance, process and supply issues lead to under-delivery to customers. ILS stabilises performance and value stream through professional management experience, expert knowledge and sustainable problem-solving competence...

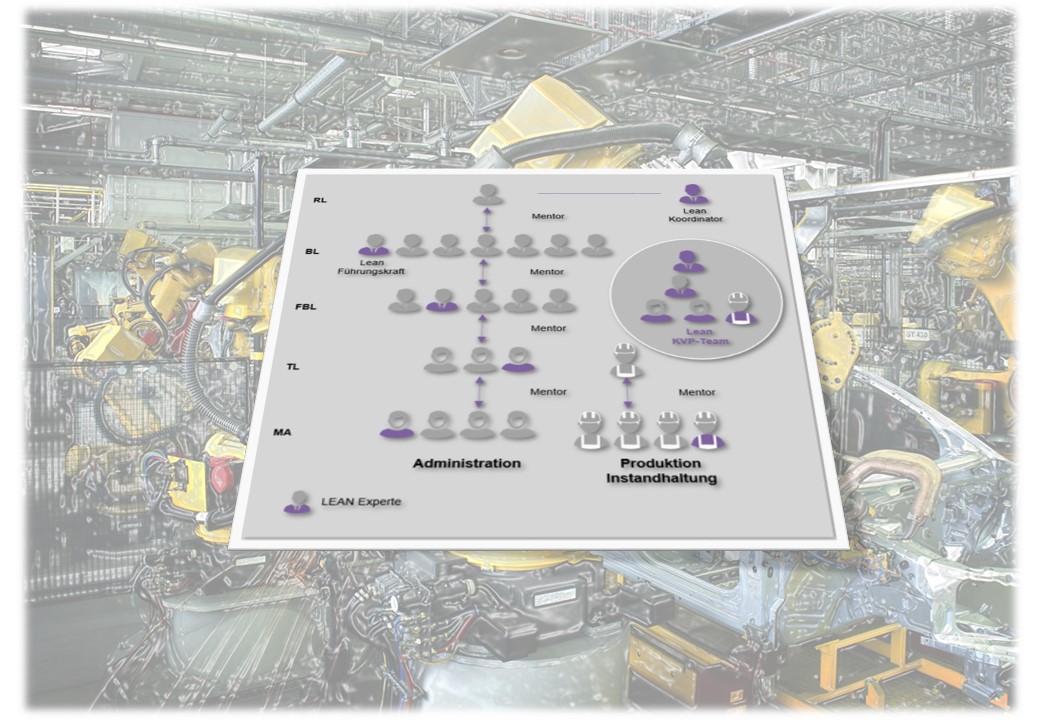

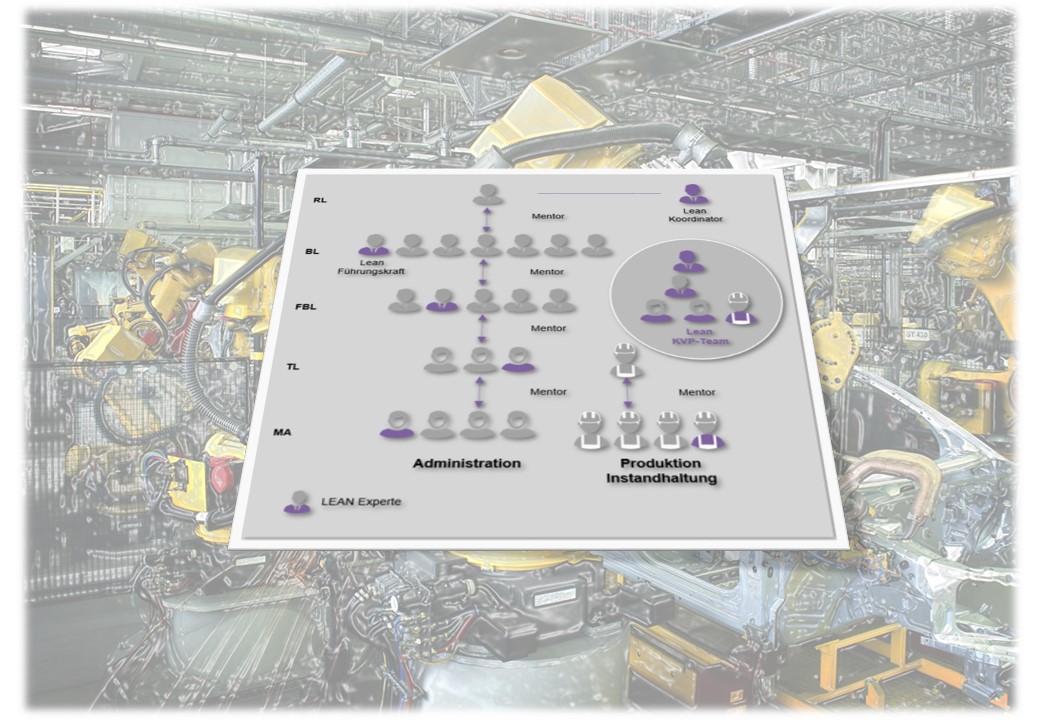

Cost-cutting initiative at a medium-sized company: Increasing efficiency in the organisation

ILS brings lean organisation to medium-sized companies! An organisational structure perfectly tailored to your goals. It all began with a thorough analysis of internal processes. Expanding responsibilities leads to success.

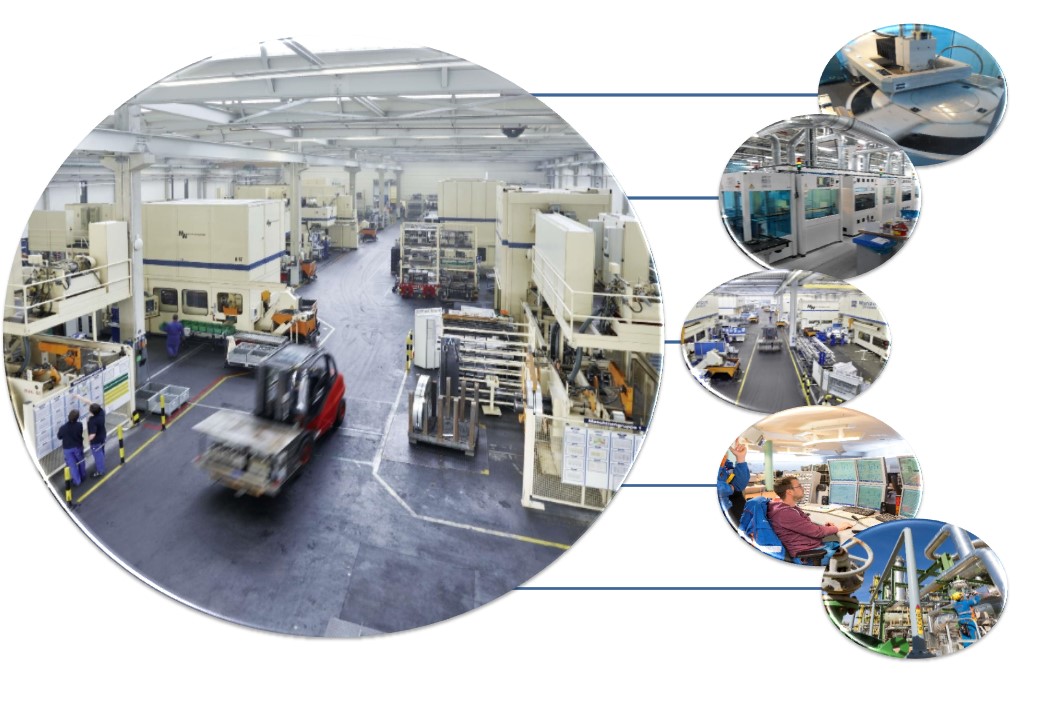

Factory planning: Near Helsinki

Fascinating factory planning project near Helsinki: To kick off the project, we carried out a quick review of the current production process in the factory. The existing database was checked for "value-adding" and "non-value-adding" parts. In addition, we analyzed the material flow of both prefabrication and the main lines in order to identify optimization opportunities. Our task is now to design a material flow that is optimally tailored to the customer's needs, focusing in particular on the layout of the workstations using lean management methods. The aim is to significantly reduce production costs and increase output.

Expansion: MIAS doubles production volume in Hungary

.webp)

Expansion: MIAS doubles production volume in Hungary

The Karlsruhe-based consultancy Integrated Logistics Systems (ILS) has taken on the role of general contractor for the overall planning of the production and logistics processes for the Hungarian site in Gyöngyös of the Munich-based Jungheinrich subsidiary Mias. As the company has announced, the plant located around 50 kilometers northeast of Budapest is considered the central production site for storage and retrieval machines (SRMs) for Europe and overseas...

ILS-MEDIA LIBRARY

DOWNLOADS

INTEGRATED LOGISTICS SYSTEMS

Postweg 51

D-76187 Karlsruhe

Germany

Tel: +49 721-97037-27

E-Mail: info@ilsystem.de

Company

With 20 years of experience, we are a global company specializing in energy consulting, energy consulting, project management, IT systems, factory planning and the optimization of production and logistics processes.

Our extensive expertise and experience enable us to provide innovative solutions for companies worldwide. We have successfully implemented over 250 projects, achieving sustainable results in various industries.

Our areas of activity include:

Consulting:

Cost Reduction ProgramOur consulting services help you achieve your strategic goals and successfully drive your business forward. We offer tailor-made solutions to identify bottlenecks, optimize processes and achieve competitive advantages.

Cost reduction projects (Cost Down Projects):

We specialize in optimizing your costs and increasing the competitiveness of your company. Our cost reduction projects are designed to analyze your process chain from start to finish and identify potential for cost savings.

We specialize in optimizing your costs and increasing the competitiveness of your company. Our cost reduction projects are designed to analyze your process chain from start to finish and identify potential for cost savings.

Project management:

With our experienced project management team, we offer comprehensive support in the planning, coordination and implementation of projects. We ensure that your projects are completed on time and within budget.

With our experienced project management team, we offer comprehensive support in the planning, coordination and implementation of projects. We ensure that your projects are completed on time and within budget.

Engineering:

Our experts support you in improving your energy efficiency and implementing sustainable energy systems. We analyze your energy consumption, identify potential savings and develop solutions to cut costs and reduce environmental impact.

Energy consulting and renewable energies:

Energy consulting for non-residential buildings: 90% fuel savingsAs experts in energy efficiency and renewable energies, we offer you comprehensive consulting services. We analyze your energy consumption, identify potential savings and develop tailor-made concepts for the use of renewable energies. We work together to reduce your ecological footprint and save costs.

Energy consulting for non-residential buildings: 90% fuel savingsAs experts in energy efficiency and renewable energies, we offer you comprehensive consulting services. We analyze your energy consumption, identify potential savings and develop tailor-made concepts for the use of renewable energies. We work together to reduce your ecological footprint and save costs.

Factory planning:

Lean_4.0 Our factory planning services include the design and optimization of production and logistics processes. We analyze your operational processes, identify bottlenecks and develop efficient solutions to increase productivity and reduce costs. We also apply lean management principles.

Lean_4.0 Our factory planning services include the design and optimization of production and logistics processes. We analyze your operational processes, identify bottlenecks and develop efficient solutions to increase productivity and reduce costs. We also apply lean management principles.

IT systems:

Our IT solutions improve the performance of your technical systems. We support you in the implementation and maintenance of networks, databases, software solutions and security systems to meet your operational requirements.

At ILS, customer satisfaction is our top priority. Our goal is to achieve sustainable results for our clients and grow their business.

Contact us today to learn more about our services and how we can help you optimize your production and logistics processes. We look forward to working with you and making your business successful.

Core Services I Experience

| Consulting > | Experience = 20 Years |

| Engineering > | Customer Service = worldwide |

| Systems > | Project Supported > 221 |

| Core Areas | |

| Renewable Energy > | Process Optimization > |

| PV-Systems > | Factory Planning / Implementation > |

| Hydrogen > | Production Planning / Control > |

| Energy Consulting> | Project management / Lean Management > |

| Efficiency improvement > | Logistics Planning > |