LATEST NEWS

48V battery production ramp-up highly critical: ILS stabilises output

The ramp-up of 48V battery production at automotive suppliers is highly critical. The current problems are manifold. Among other things, poor performance, process and supply issues lead to under-delivery to customers. ILS stabilises performance and value stream through professional management experience, expert knowledge and sustainable problem-solving competence...

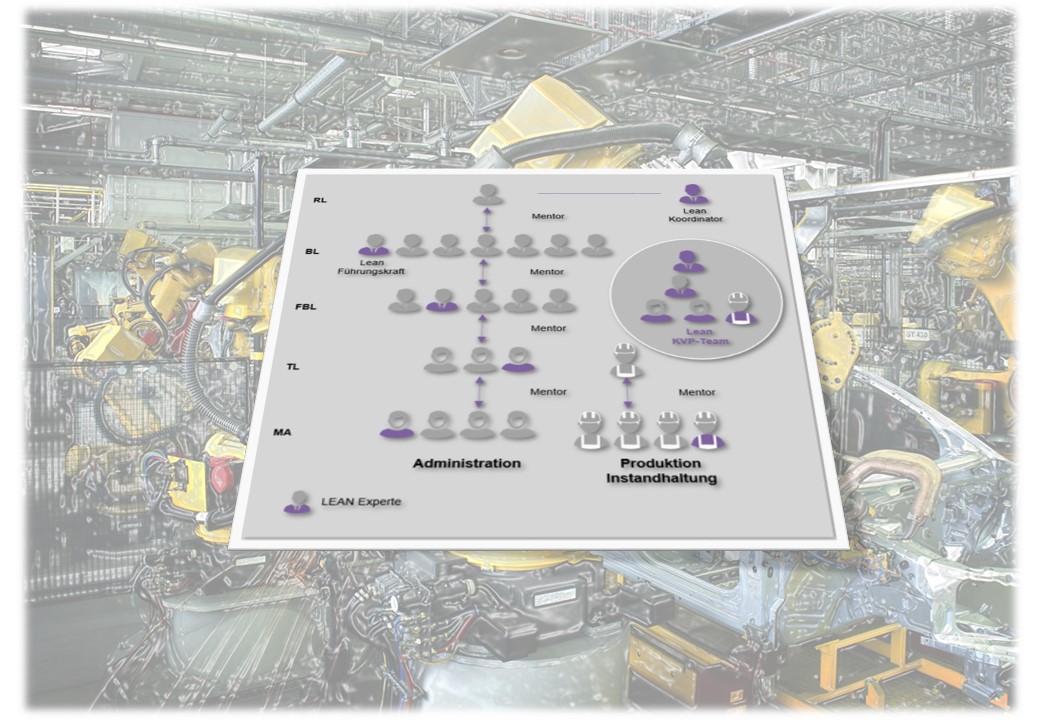

Cost-cutting initiative at a medium-sized company: Increasing efficiency in the organisation

ILS brings lean organisation to medium-sized companies! An organisational structure perfectly tailored to your goals. It all began with a thorough analysis of internal processes. Expanding responsibilities leads to success.

Factory planning: Near Helsinki

Fascinating factory planning project near Helsinki: To kick off the project, we carried out a quick review of the current production process in the factory. The existing database was checked for "value-adding" and "non-value-adding" parts. In addition, we analyzed the material flow of both prefabrication and the main lines in order to identify optimization opportunities. Our task is now to design a material flow that is optimally tailored to the customer's needs, focusing in particular on the layout of the workstations using lean management methods. The aim is to significantly reduce production costs and increase output.

Expansion: MIAS doubles production volume in Hungary

.webp)

Expansion: MIAS doubles production volume in Hungary

The Karlsruhe-based consultancy Integrated Logistics Systems (ILS) has taken on the role of general contractor for the overall planning of the production and logistics processes for the Hungarian site in Gyöngyös of the Munich-based Jungheinrich subsidiary Mias. As the company has announced, the plant located around 50 kilometers northeast of Budapest is considered the central production site for storage and retrieval machines (SRMs) for Europe and overseas...

ILS-MEDIA LIBRARY

DOWNLOADS

INTEGRATED LOGISTICS SYSTEMS

Postweg 51

D-76187 Karlsruhe

Germany

Tel: +49 721-97037-27

E-Mail: info@ilsystem.de

VISIONS > SUSTAINABILITY > FUTURE

Consulting I Engineering I Systems

We transform industrial sites and plan the factories of the future

Systematically realigning industrial sites

Today, industrial production sites are under structural pressure to change. Rising costs, regulatory requirements, a shortage of skilled workers and new market conditions require a fundamental strategic realignment.

ILSystems develops holistic transformation programs for existing locations – with a clear definition of goals, a resilient implementation structure and measurable results.

Strategic location transformation

Systematically realigning industrial sites.

We support you in sustainably developing your production sites – with clear target visions, resilient roadmaps and measurable results.

- Analysis of existing site structures

- Development of a strategic vision

- Transformations-Roadmaps

- Organizational and management structures

- Qualification and training concepts

- Performance programs for sustainable performance improvement

Factory planning & production setup

Planning and implementing high-performance production structures

We do not think of factory planning in isolation, but as an integral part of site development – from greenfield projects to the optimization of existing plants.

- Factory and layout planning

- Material flow and logistics concepts

- Greenfield and brownfield projects

- Relocation of production & site development

- Capacity and structural planning

- Integration of technical and organizational requirements

We do not think of factory planning as isolation from a technical point of view, but as part of strategic site development.

Process & Performance Optimization

Increase productivity, stabilize structures, empower organization.

Sustainable competitiveness is created through robust processes, empowerment of teams and targeted performance improvements.

- Introduction of lean production systems

- Process and Value Stream Optimization

- Reduce lead time and inventory

- Performance and KPI systems

- Operational Excellence Programme

- Empowering managers and employees

Case Study

Transformation of a refinery site in Leuna

An energy-intensive industrial site faced strategic challenges: outdated processes, a shortage of skilled workers and a lack of future orientation. ILSystems designed and implemented the transformation program – starting with the analysis, through organizational and process modernization, to performance enhancement and employee qualification. This project shows how site development, process innovation and organizational culture can be effective together – and how a traditional industrial site can be made fit for the future.

Click here for the complete case study: "Lean 4 Leuna – Transformation of an industrial site"

Why ILSystems?

Transformation needs more than concepts

Transformation needs more than concepts – it needs the strength to implement. Many consultancies provide analyses. We combine strategic thinking with operational excellence, accompany projects beyond the concept phase and take responsibility for results

ILSystems combines strategic thinking with industrial implementation competence.

We understand industrial value creation holistically

- Location strategy

- Factory and production planning

- Organizational Development

- Process and performance optimization

- Qualification of managers and employees

We don't think of isolated measures, but in integrated systems.

Experience in complex production environments

Transformation in energy-intensive and technologically demanding industries requires:

- technical understanding

- Organizational sensitivity

- resilient implementation structures

- Acceptance by workforce and management

Projects such as the site transformation in Leuna show that sustainable change is possible – if strategy, organization and production are thought of together.

Think strategically. Acting Operationally

We work at decision-making level – and at the same time close to production, processes and employees. However, it is crucial for the success of industrial transformation projects.

Implementation instead of theory

Our aim is not to develop isolated optimization measures, but to sustainably develop industrial performance.

ILSystems – Your Partner for Sustainable Industrial Transformation

Request a free initial consultation

Personal feedback within 24 hours. By phone or e-mail – just as you wish: Contact

Would you prefer to speak directly?

Just give us a call. We are there for you on weekdays from 08:00 to 17:00: Contact