LATEST NEWS

48V battery production ramp-up highly critical: ILS stabilises output

The ramp-up of 48V battery production at automotive suppliers is highly critical. The current problems are manifold. Among other things, poor performance, process and supply issues lead to under-delivery to customers. ILS stabilises performance and value stream through professional management experience, expert knowledge and sustainable problem-solving competence...

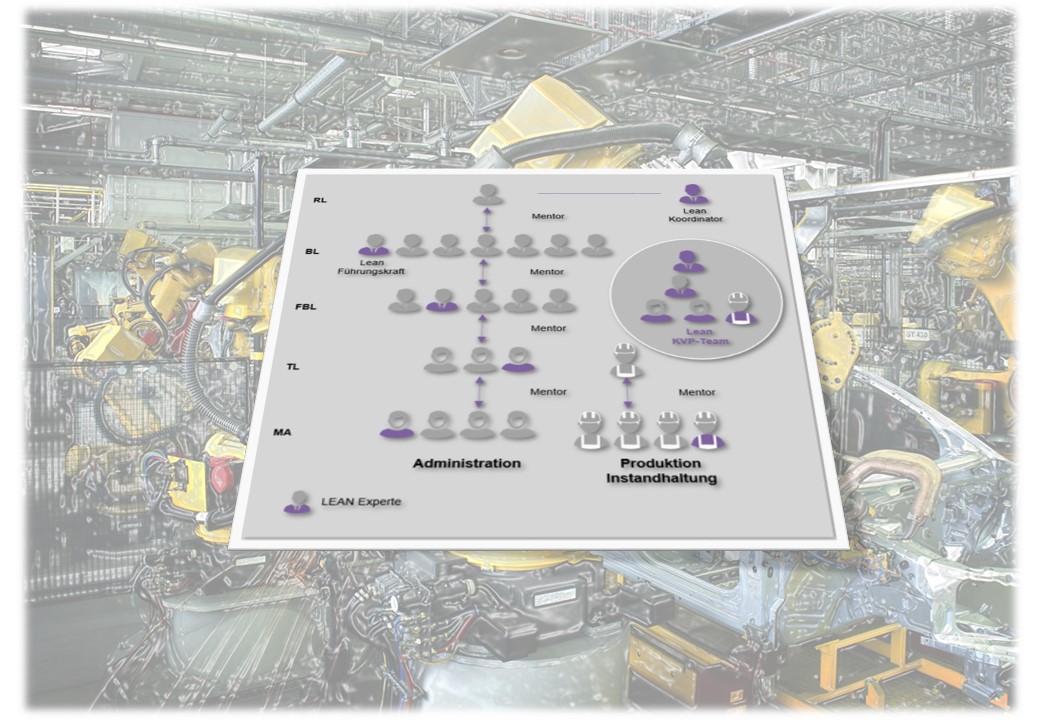

Cost-cutting initiative at a medium-sized company: Increasing efficiency in the organisation

ILS brings lean organisation to medium-sized companies! An organisational structure perfectly tailored to your goals. It all began with a thorough analysis of internal processes. Expanding responsibilities leads to success.

Factory planning: Near Helsinki

Fascinating factory planning project near Helsinki: To kick off the project, we carried out a quick review of the current production process in the factory. The existing database was checked for "value-adding" and "non-value-adding" parts. In addition, we analyzed the material flow of both prefabrication and the main lines in order to identify optimization opportunities. Our task is now to design a material flow that is optimally tailored to the customer's needs, focusing in particular on the layout of the workstations using lean management methods. The aim is to significantly reduce production costs and increase output.

Expansion: MIAS doubles production volume in Hungary

.webp)

Expansion: MIAS doubles production volume in Hungary

The Karlsruhe-based consultancy Integrated Logistics Systems (ILS) has taken on the role of general contractor for the overall planning of the production and logistics processes for the Hungarian site in Gyöngyös of the Munich-based Jungheinrich subsidiary Mias. As the company has announced, the plant located around 50 kilometers northeast of Budapest is considered the central production site for storage and retrieval machines (SRMs) for Europe and overseas...

ILS-MEDIA LIBRARY

DOWNLOADS

INTEGRATED LOGISTICS SYSTEMS

Postweg 51

D-76187 Karlsruhe

Germany

Tel: +49 721-97037-27

E-Mail: info@ilsystem.de

Restructuring

The approach to a restructuring project always depends on the challenges involved and the industry sector. Generally, we approach a restructuring project according to the strategy we have developed.

Scanning phase

During the initial phase, all the existing business processes are examined in detail. The examination entails a critical inspection and questioning of all the processes and procedures that are performed in production or in the tertiary areas. By taking a look from the outside, i.e. at a distance from the existing processes, each step is questioned with respect to its usefulness. The aim is to identify the weak points or cost drivers of the business and to tackle these through targeted measures as quickly as possible. The examination process covers the overhead areas as well as the producing sections. After the scanning process, measures to eliminate the weak points or cost drivers are defined and included in an implementation plan. Each measure has a completion deadline and a person responsible assigned to it. Implementation progress is monitored, and, if necessary, measures are initiated to ensure that the deadlines are kept.

Recognising potential – maintaining substance

Fast and accurate analyses and purposeful implementation of future-proof and targeted measures. During this phase, the focus is on setting up a transparent goal management framework.

Catalogue of measures

Training employees on topic “Lean Management”

Training employees on topic “Lean Management” Standardisation of all processes (simple, clear processes)

Standardisation of all processes (simple, clear processes) Marking or labelling all sections in production

Marking or labelling all sections in production Elimination of organisational grey zones

Elimination of organisational grey zones Elimination of ‘muda’ (waste in production)

Elimination of ‘muda’ (waste in production) Examination of all processes under the aspect of value creation

Examination of all processes under the aspect of value creation Optimisation of the production equipment under the aspect of CIP

Optimisation of the production equipment under the aspect of CIP Performing layout optimisation

Performing layout optimisation Setting up a goal management framework

Setting up a goal management framework Definition of clear goals in all areas

Definition of clear goals in all areas