LATEST NEWS

48V battery production ramp-up highly critical: ILS stabilises output

The ramp-up of 48V battery production at automotive suppliers is highly critical. The current problems are manifold. Among other things, poor performance, process and supply issues lead to under-delivery to customers. ILS stabilises performance and value stream through professional management experience, expert knowledge and sustainable problem-solving competence...

Cost-cutting initiative at a medium-sized company: Increasing efficiency in the organisation

ILS brings lean organisation to medium-sized companies! An organisational structure perfectly tailored to your goals. It all began with a thorough analysis of internal processes. Expanding responsibilities leads to success.

Factory planning: Near Helsinki

Fascinating factory planning project near Helsinki: To kick off the project, we carried out a quick review of the current production process in the factory. The existing database was checked for "value-adding" and "non-value-adding" parts. In addition, we analyzed the material flow of both prefabrication and the main lines in order to identify optimization opportunities. Our task is now to design a material flow that is optimally tailored to the customer's needs, focusing in particular on the layout of the workstations using lean management methods. The aim is to significantly reduce production costs and increase output.

Expansion: MIAS doubles production volume in Hungary

.webp)

Expansion: MIAS doubles production volume in Hungary

The Karlsruhe-based consultancy Integrated Logistics Systems (ILS) has taken on the role of general contractor for the overall planning of the production and logistics processes for the Hungarian site in Gyöngyös of the Munich-based Jungheinrich subsidiary Mias. As the company has announced, the plant located around 50 kilometers northeast of Budapest is considered the central production site for storage and retrieval machines (SRMs) for Europe and overseas...

ILS-MEDIA LIBRARY

DOWNLOADS

INTEGRATED LOGISTICS SYSTEMS

Postweg 51

D-76187 Karlsruhe

Germany

Tel: +49 721-97037-27

E-Mail: info@ilsystem.de

Lean Management

Lean Management Consulting - practical examples - sustainable process -optimization

Our mission is to firmly integrate lean management into companies. We increase productivity, flexibility, and quality across the entire manufacturing process.

With our lean management consulting services, we help eliminate waste, shorten throughput times, and sustainably improve value creation in the workplace.

Lean management in practice – methods and measures

Lean management in practice – methods and measures

We rely on proven lean manufacturing methods such as:

-

Setup workshops to reduce changeover times

-

Value stream analyses for optimizing material and information flow

-

5S measures for systematic workplace organization

These lean measures lead to measurable success and demonstrate how practical examples of lean management can improve everyday business operations in the long term.

Lean 4.0 – Digitalization in Lean System Management

As part of Lean System Management, we combine digital technologies with classic lean principles.

The result:

-

more precise process control

- greater transparency

-

data-driven decisions

-

Intelligent networking of production and logistics

This is how we bridge the gap between traditional lean and the requirements of Industry 4.0.

Goals of lean management

Our lean management goals are clearly defined and directly visible:

-

Increase in efficiency

-

Improvement of product quality

-

Optimize production processes

-

greater flexibility in manufacturing

-

Transparent processes for employees and managers

These goals form the basis for sustainable process optimization through lean management.

Go to Gemba – experience sustainable process optimization

The key to effective lean management lies directly at the point of value creation: go to gemba.

Only through observation and analysis on site can effective lean measures be developed that will stand the test of everyday use and become firmly established in the long term.

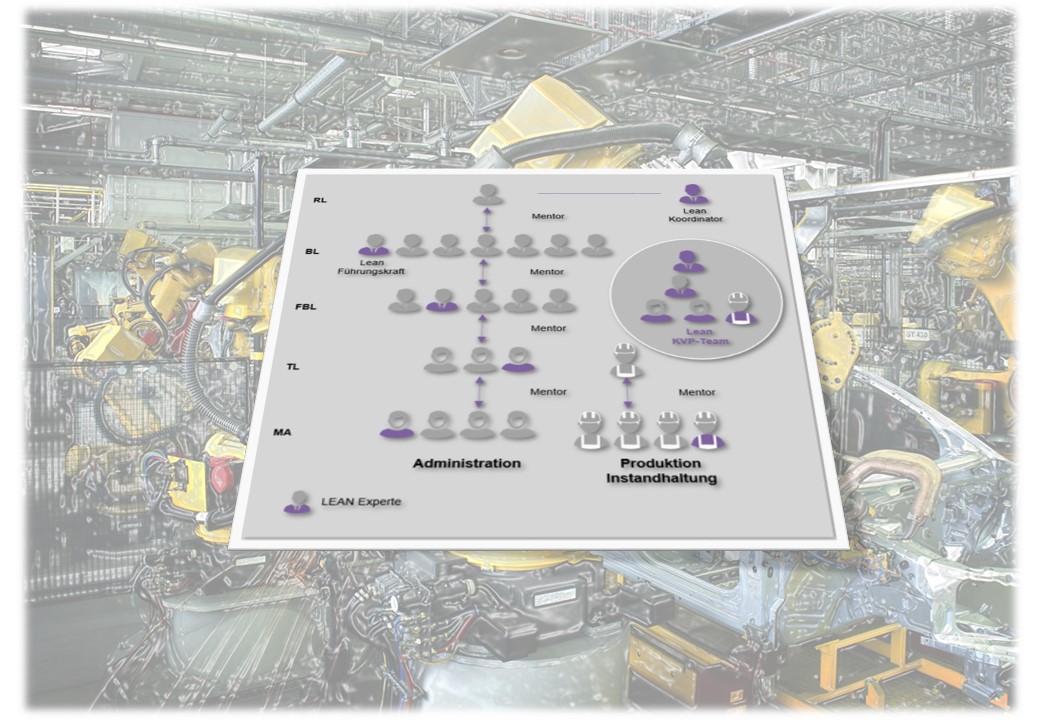

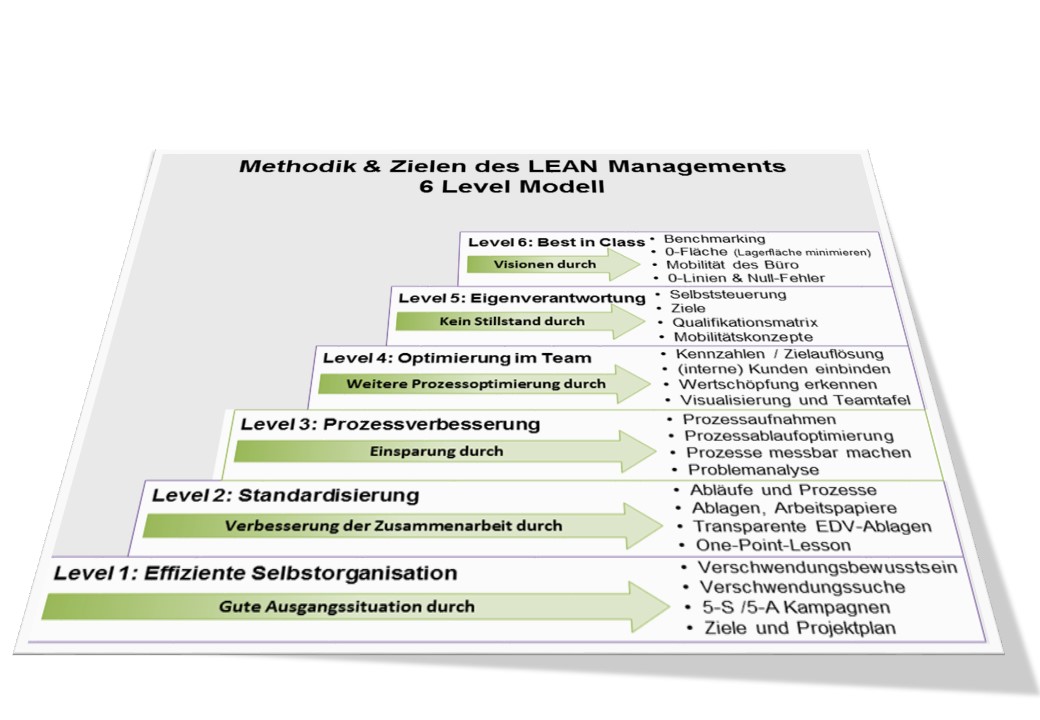

The 6-level model of lean management

Our 6-level model shows the way to lean, sustainable processes and a lean culture that is lived and breathed within the company. Step by step, we develop organizations, teams, and employees toward excellence and best-in-class performance.

Level 1: Efficient self-organization

Level 1: Efficient self-organization

The basis for this is a clear structure in everyday work. Employees organize tasks and processes efficiently to create transparency and stability.

Level 2: Standardization

Repeatable processes are defined and standardized. Standards ensure quality, reduce sources of error, and lay the foundation for continuous improvement.

Level 3: Process improvement

Processes are systematically optimized using methods such as Kaizen or value stream analysis. The aim is to avoid waste and increase productivity.

Level 4: Optimization in a team

Teams work together across departments to improve processes along the entire value chain. This promotes communication, efficiency, and a shared sense of responsibility.

Level 5: Personal responsibility

Employees take responsibility for quality, efficiency, and results. A lean culture emerges in which everyone actively initiates and helps shape improvements.

Level 6: Best in Class

The company achieves excellence: lean processes, highly motivated teams, and continuous innovation. Benchmarking and best practices ensure your long-term competitiveness.

Lean-Thinking – Efficiency reimagined

We are your global partner for the successful implementation of lean management. From the analysis of existing processes to practical implementation on the production line, we provide your company with comprehensive support.

We work with you to design lean, efficient processes—from planning to implementation. Our focus is on lean methods and strategies that reduce waste, ensure quality, and increase productivity in the long term.

Our proven methods include:

-

One Piece Flow – continuous production without downtime

-

inventory reduction – Avoid tying up capital, increase flexibility

-

quality improvement – Establish stable, error-free processes

-

increase in productivity – Targeted exploitation of efficiency potential

Our 5-step approach

-

Define value from the customer's perspective

Consistently align processes with customer needs

-

Identify value streams

Optimize value-adding activities, avoid duplication of work and waste

-

Apply the pull and flow principle

Establish demand-driven processes and eliminate delays

-

Empowering employees

Actively involve all participants and promote responsibility

-

Living continuous improvement

Regularly review processes and continuously optimize them

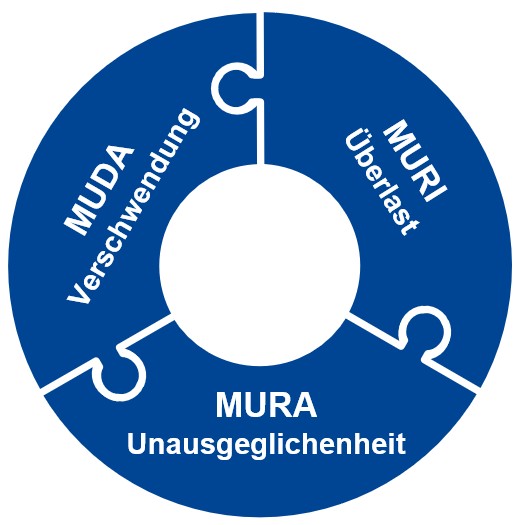

Lean Thinking – Identify and eliminate waste

KAIZEN, also known as continuous improvement, is more than just a method—it is a holistic way of thinking and a corporate culture. The aim is to constantly question processes, eliminate inefficiencies, and create added value for customers.

In order to achieve genuine improvement, three key causes of waste must be identified and consistently eliminated:

MURI – Avoid overloading

MURI – Avoid overloading

Overloading of people and machines is caused by planning errors, a lack of process harmonization, or unrealistic specifications. This leads to quality problems, breakdowns, and inefficiency. Lean management focuses on realistic timing and optimized processes.

MURA – Eliminate imbalance in the system

Irregularities and fluctuations in the workflow create bottlenecks or overload individual areas. The goal is a harmonious overall process that makes optimal use of resources and avoids peak loads.

MUDA – Eliminate waste

MUDA refers to all activities that do not create added value for the customer: unnecessary travel, waiting times, overproduction, defective products, or excessive inventory. Lean thinking systematically reduces these non-value-adding activities.

By consistently applying MURI, MURA, and MUDA, companies can create stable processes, satisfied employees, and a sustainable increase in efficiency.

Services

| Lean Management > | Lean Projektmanagement > |

| Lean Manufacturing > | Value Stream Mapping > |

| Lean Production > | Lean 4 Logistics > |

| Lean Administration > | Lean Energy management > |

| Lean Organization > | Lean Strategy > |

| Expert Services | |

| Learn-Lean-Thinking > | Value Stream design > |

| Recognize muda > | Determine Lean Customer Cycle > |

| Lean Training modules > | Kanban-Control of Production > |

| Introduction Lean 6 Level Model > | Spaghetti-Diagram > |

| Go to Gemba > | Setup-Workshop > |

| MTM / Methods Time Measurement > | TPS / Toyota Productions System |