LATEST NEWS

48V battery production ramp-up highly critical: ILS stabilises output

The ramp-up of 48V battery production at automotive suppliers is highly critical. The current problems are manifold. Among other things, poor performance, process and supply issues lead to under-delivery to customers. ILS stabilises performance and value stream through professional management experience, expert knowledge and sustainable problem-solving competence...

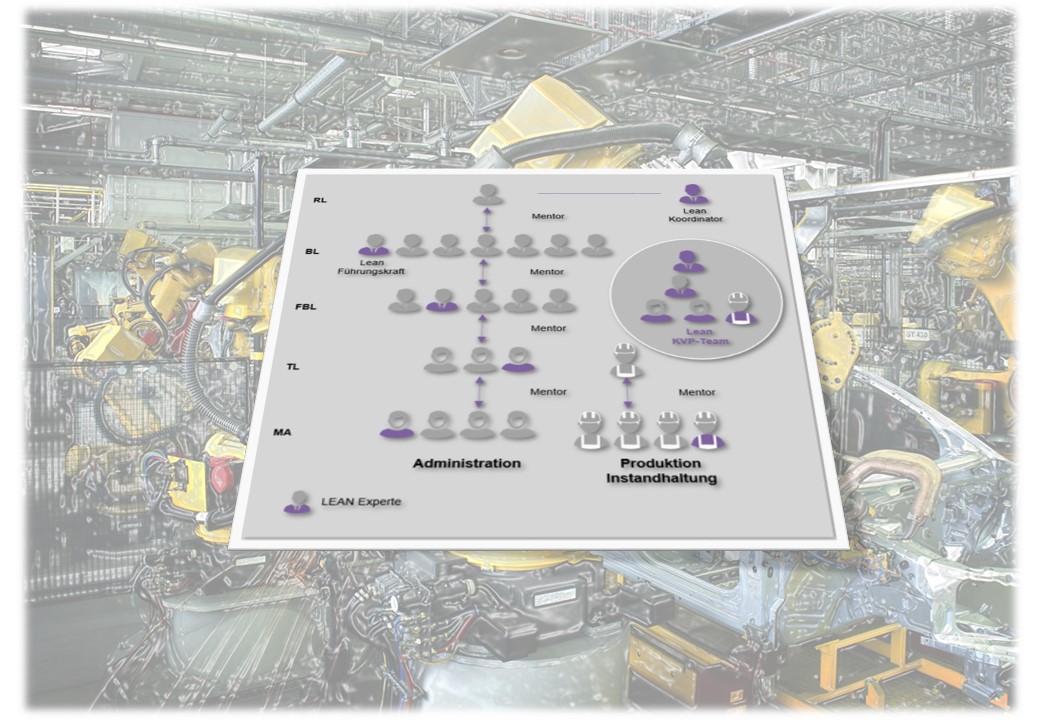

Cost-cutting initiative at a medium-sized company: Increasing efficiency in the organisation

ILS brings lean organisation to medium-sized companies! An organisational structure perfectly tailored to your goals. It all began with a thorough analysis of internal processes. Expanding responsibilities leads to success.

Factory planning: Near Helsinki

Fascinating factory planning project near Helsinki: To kick off the project, we carried out a quick review of the current production process in the factory. The existing database was checked for "value-adding" and "non-value-adding" parts. In addition, we analyzed the material flow of both prefabrication and the main lines in order to identify optimization opportunities. Our task is now to design a material flow that is optimally tailored to the customer's needs, focusing in particular on the layout of the workstations using lean management methods. The aim is to significantly reduce production costs and increase output.

Expansion: MIAS doubles production volume in Hungary

.webp)

Expansion: MIAS doubles production volume in Hungary

The Karlsruhe-based consultancy Integrated Logistics Systems (ILS) has taken on the role of general contractor for the overall planning of the production and logistics processes for the Hungarian site in Gyöngyös of the Munich-based Jungheinrich subsidiary Mias. As the company has announced, the plant located around 50 kilometers northeast of Budapest is considered the central production site for storage and retrieval machines (SRMs) for Europe and overseas...

ILS-MEDIA LIBRARY

DOWNLOADS

INTEGRATED LOGISTICS SYSTEMS

Postweg 51

D-76187 Karlsruhe

Germany

Tel: +49 721-97037-27

E-Mail: info@ilsystem.de

Supply Chain

|

| Picture: holistic view of supply chain |

Over the last few decades, a certain autonomisation of dynamics and complexity has become apparent in commerce and manufacturing.

On the one hand, production is relocated due to cost and wage issues.

On the other hand, growth can only be achieved through opening up new markets. Internal process optimisation is no longer proving sufficient, since its savings and improvement potentials have been largely exhausted.

A strategic reorientation of the production and logistics network is essential to avoid falling behind in the competitive environment. What is needed is an innovative solution for design and optimisation in procurement, transportation, production and distribution.

Supply Chain Management

With our supportive optimisation in procurement, transportation, production and distribution planning, we lay the foundation for harmonious logistics networks and introduce you to promising logistics strategies. During the implementation phase of the initiated optimisation measures, we take over the management of the process.

Quality, costs and transparency can be optimised in all links of the chain; from your suppliers, through your production and then all the way to the customer.

Speak to us and make use of our expertise and our practical experience.

Benefits to you

Optimisation of supplier quality and supplier evaluation

Optimisation of supplier quality and supplier evaluation Reduction in delivery times

Reduction in delivery times Optimisation of material stock levels along the supply chain

Optimisation of material stock levels along the supply chain Increase in delivery reliability

Increase in delivery reliability Reduction in logistics component of product cost

Reduction in logistics component of product cost