LATEST NEWS

48V battery production ramp-up highly critical: ILS stabilises output

The ramp-up of 48V battery production at automotive suppliers is highly critical. The current problems are manifold. Among other things, poor performance, process and supply issues lead to under-delivery to customers. ILS stabilises performance and value stream through professional management experience, expert knowledge and sustainable problem-solving competence...

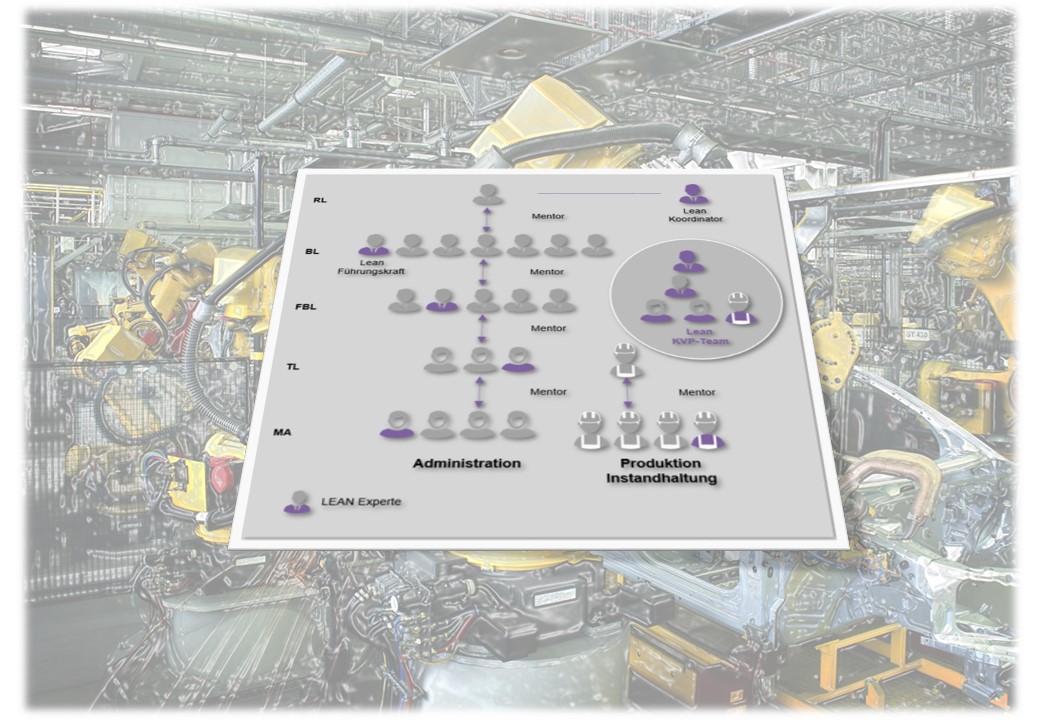

Cost-cutting initiative at a medium-sized company: Increasing efficiency in the organisation

ILS brings lean organisation to medium-sized companies! An organisational structure perfectly tailored to your goals. It all began with a thorough analysis of internal processes. Expanding responsibilities leads to success.

Factory planning: Near Helsinki

Fascinating factory planning project near Helsinki: To kick off the project, we carried out a quick review of the current production process in the factory. The existing database was checked for "value-adding" and "non-value-adding" parts. In addition, we analyzed the material flow of both prefabrication and the main lines in order to identify optimization opportunities. Our task is now to design a material flow that is optimally tailored to the customer's needs, focusing in particular on the layout of the workstations using lean management methods. The aim is to significantly reduce production costs and increase output.

Expansion: MIAS doubles production volume in Hungary

.webp)

Expansion: MIAS doubles production volume in Hungary

The Karlsruhe-based consultancy Integrated Logistics Systems (ILS) has taken on the role of general contractor for the overall planning of the production and logistics processes for the Hungarian site in Gyöngyös of the Munich-based Jungheinrich subsidiary Mias. As the company has announced, the plant located around 50 kilometers northeast of Budapest is considered the central production site for storage and retrieval machines (SRMs) for Europe and overseas...

ILS-MEDIA LIBRARY

DOWNLOADS

INTEGRATED LOGISTICS SYSTEMS

Postweg 51

D-76187 Karlsruhe

Germany

Tel: +49 721-97037-27

E-Mail: info@ilsystem.de

Kanban/E-Kanban

Setting up Kanban system involving suppliers

A tried & tested and innovative method for requesting production supplies (pull system).

Once installed, the Kanban system is virtually self-operating.

Our experience shows that when a Kanban ‘pull’ system is set up with a supplier, the transport costs remain the same as if an internal Kanban pull system is set up within the production cycle.

This requires existing transport concepts to be adapted to the Kanban pull system; and quality problems and deficiencies in the delivery time-keeping will become apparent in the process. These deficiencies should be rectified before the introduction of the Kanban pull system.

We have the experience and the competence to take over the entire project management for the introduction of the Kanban pull system.

We provide a guarantee for the entire consulting and implementation process.

E-Kanban

The extremely fast development of the Internet over the last few years and its open structure create ideal conditions for its use as the communication channel for logistical processes. Our aim is to simplify customer-specific process flows through the consistent use of modern information technologies such as the Internet or radio links with existing networks. In addition to the networking of the individual production stages, the extension of the information channels all the way to the end customer via the Internet represents an important quality challenge for our consultants compared to traditional logistics. The consistent further development of e-Kanban inevitably results in the automation of internal and external means of transport, such as forklift trucks and HGVs. Autonomous truck systems with a certain level of intelligence will form the backbone of internal transport logistics in the automotive industry in the future (see reference list). Savings potentials of up to 50% are realised through these measures.

Services:

Truck guidance system

Truck guidance system Picking applications

Picking applications Pick-by-voice

Pick-by-voice