LATEST NEWS

48V battery production ramp-up highly critical: ILS stabilises output

The ramp-up of 48V battery production at automotive suppliers is highly critical. The current problems are manifold. Among other things, poor performance, process and supply issues lead to under-delivery to customers. ILS stabilises performance and value stream through professional management experience, expert knowledge and sustainable problem-solving competence...

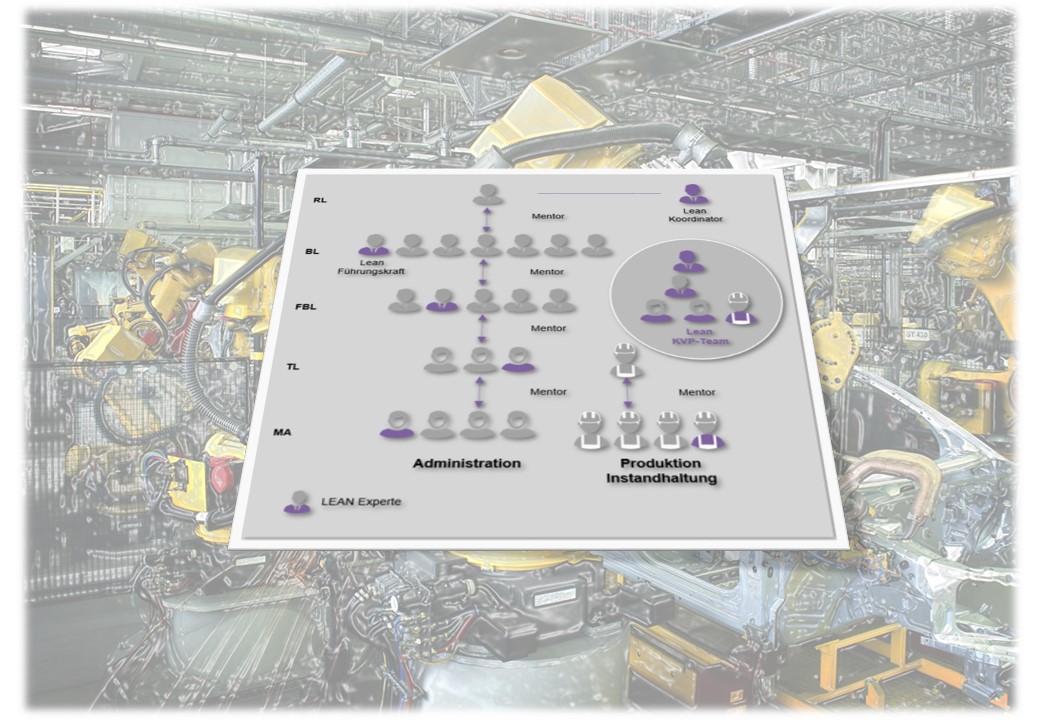

Cost-cutting initiative at a medium-sized company: Increasing efficiency in the organisation

ILS brings lean organisation to medium-sized companies! An organisational structure perfectly tailored to your goals. It all began with a thorough analysis of internal processes. Expanding responsibilities leads to success.

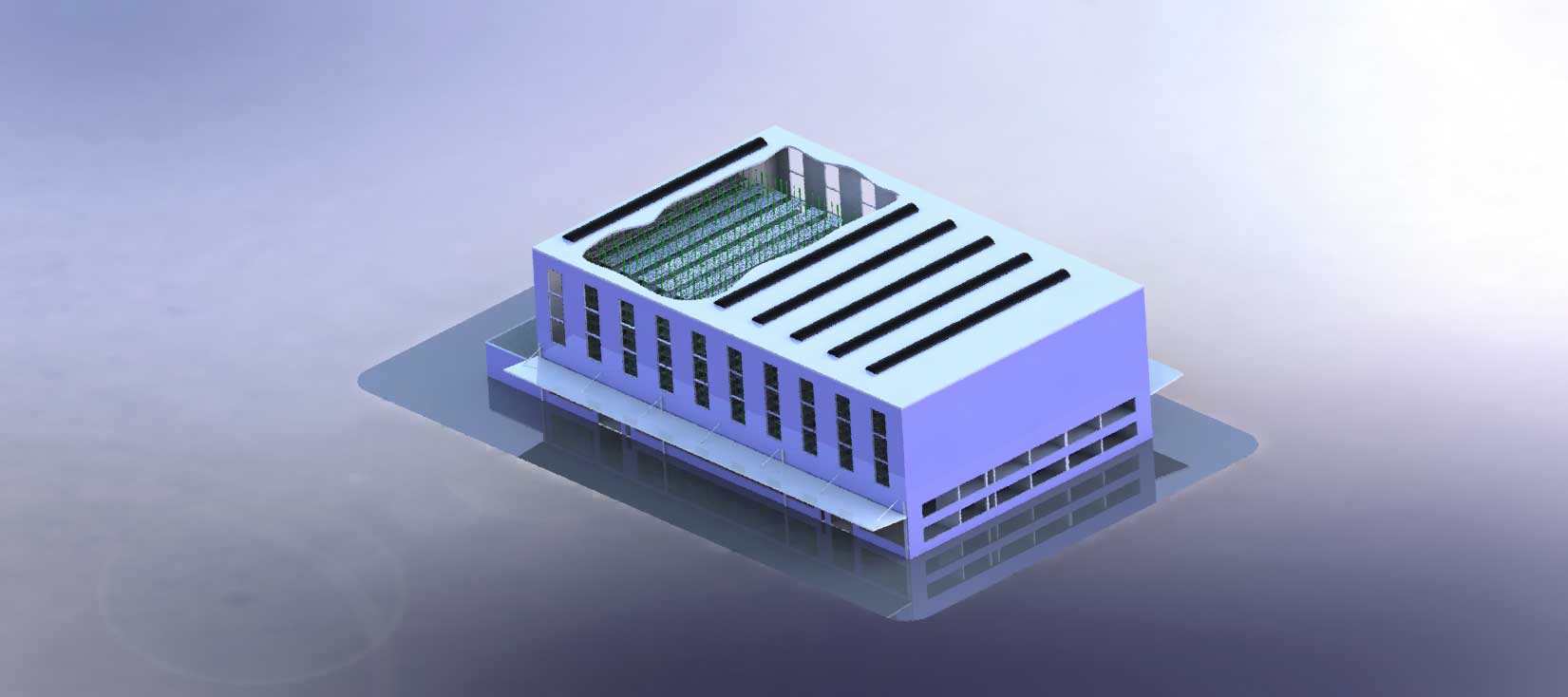

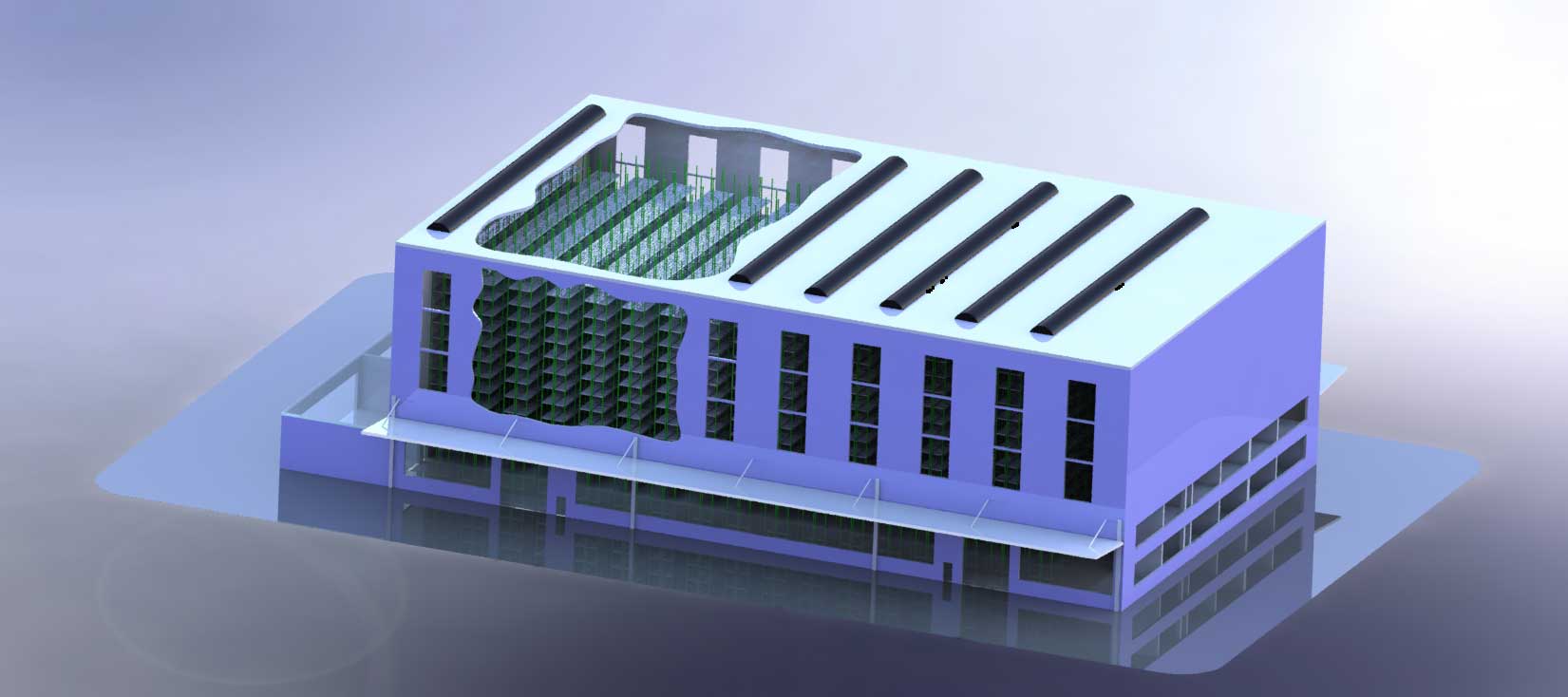

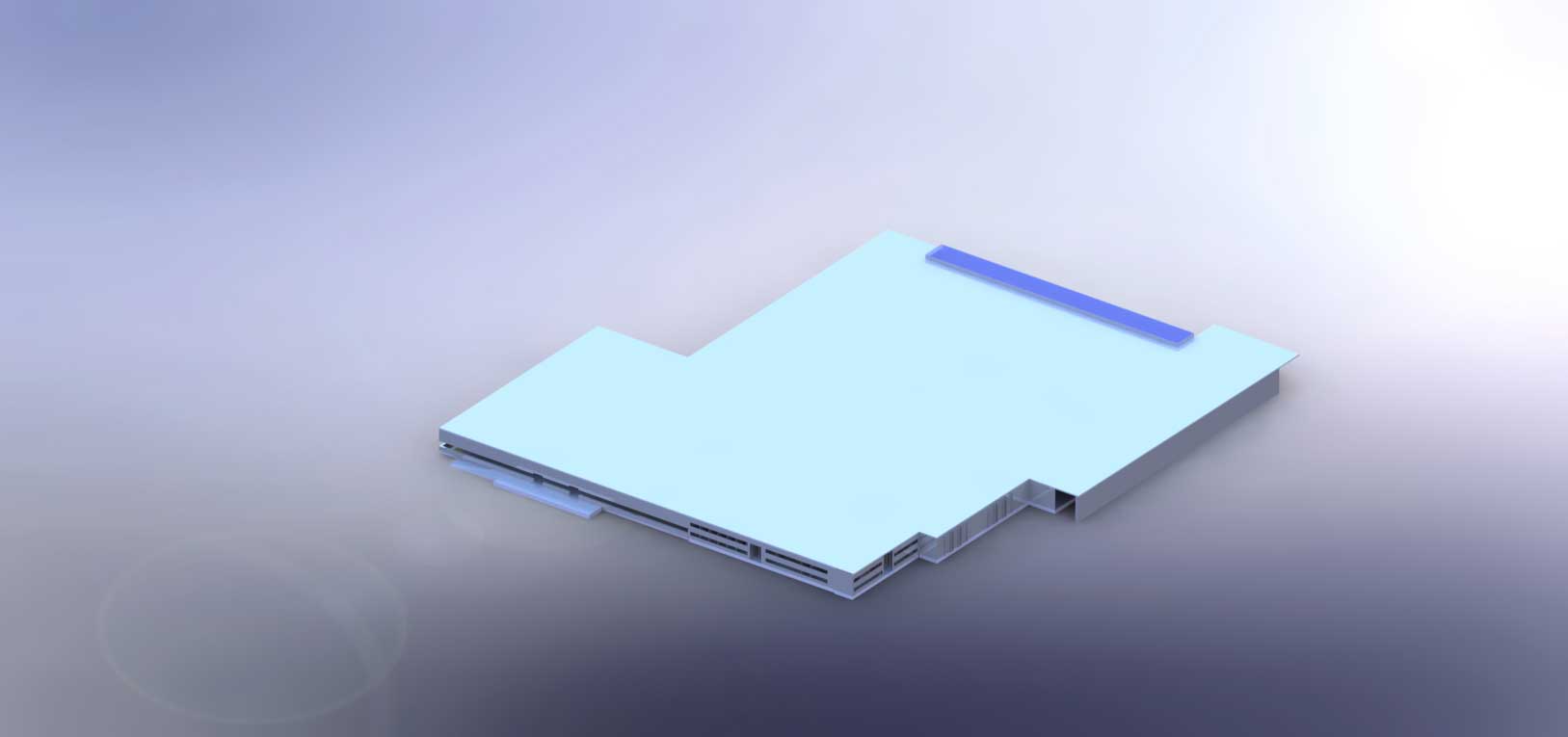

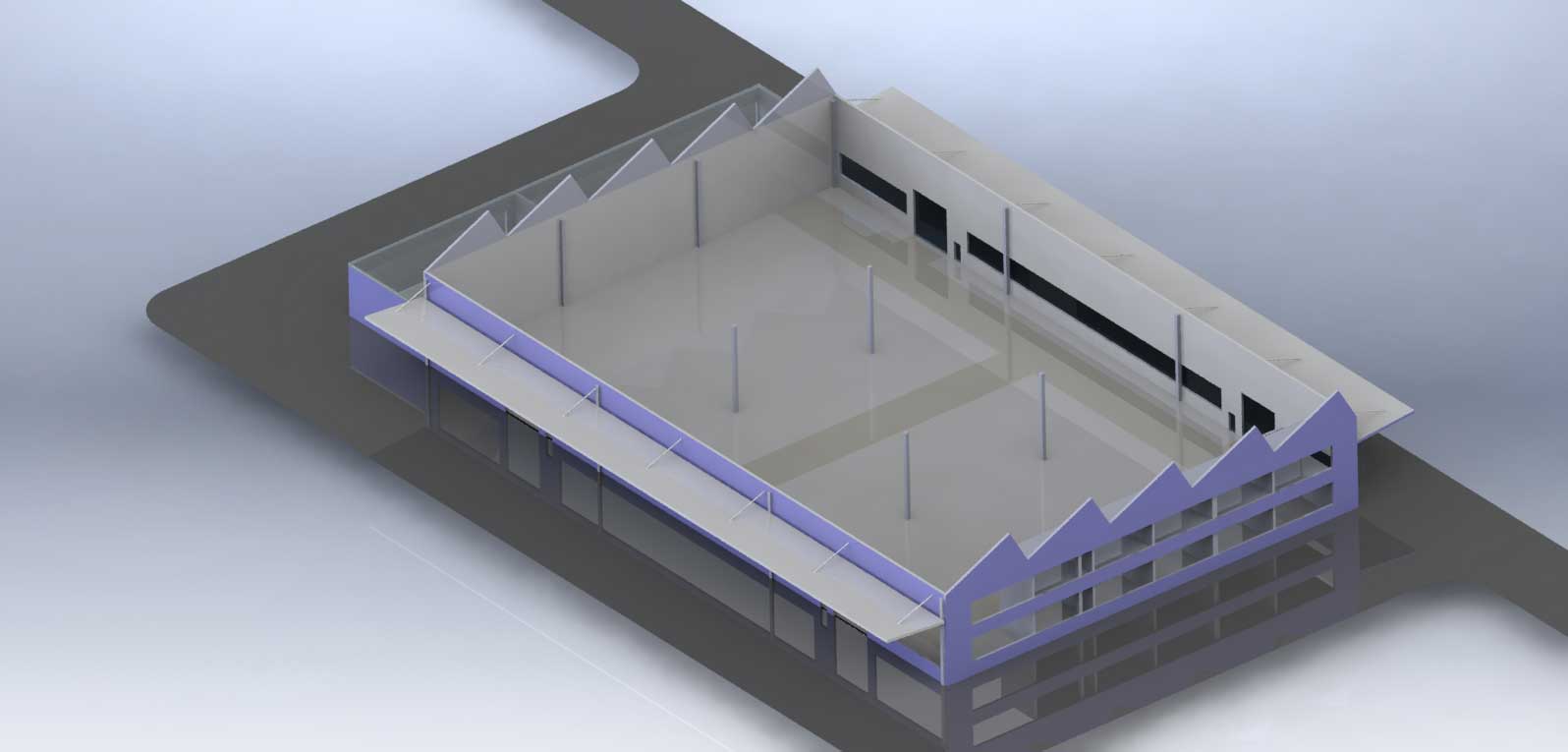

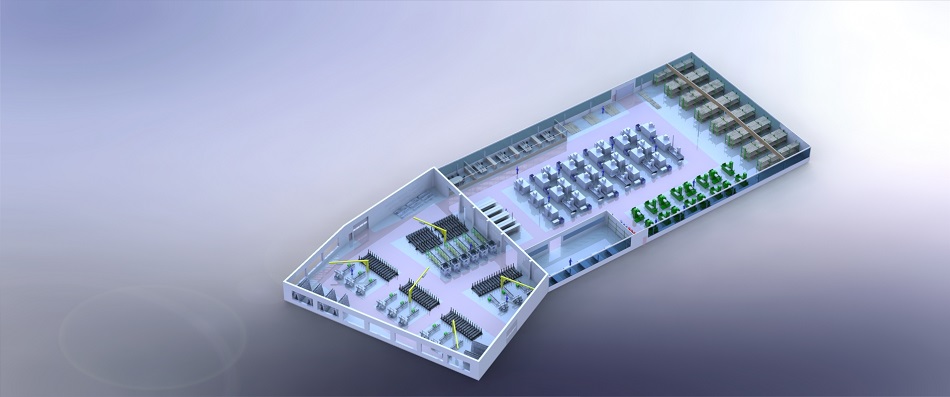

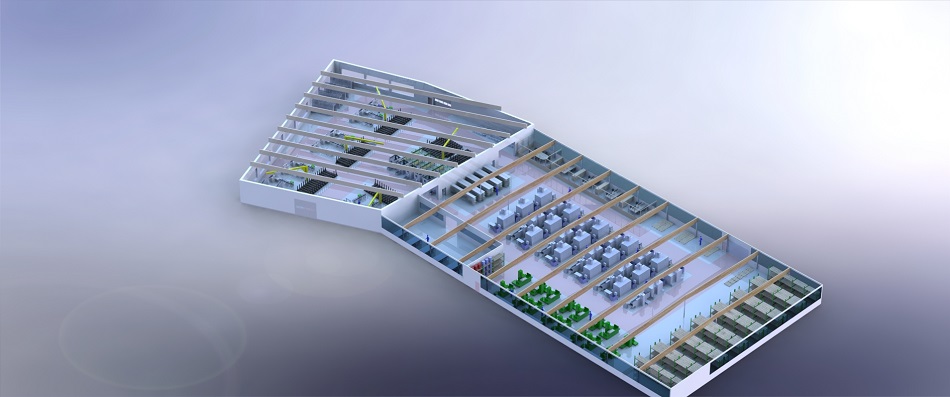

Factory planning: Near Helsinki

Fascinating factory planning project near Helsinki: To kick off the project, we carried out a quick review of the current production process in the factory. The existing database was checked for "value-adding" and "non-value-adding" parts. In addition, we analyzed the material flow of both prefabrication and the main lines in order to identify optimization opportunities. Our task is now to design a material flow that is optimally tailored to the customer's needs, focusing in particular on the layout of the workstations using lean management methods. The aim is to significantly reduce production costs and increase output.

Expansion: MIAS doubles production volume in Hungary

.webp)

Expansion: MIAS doubles production volume in Hungary

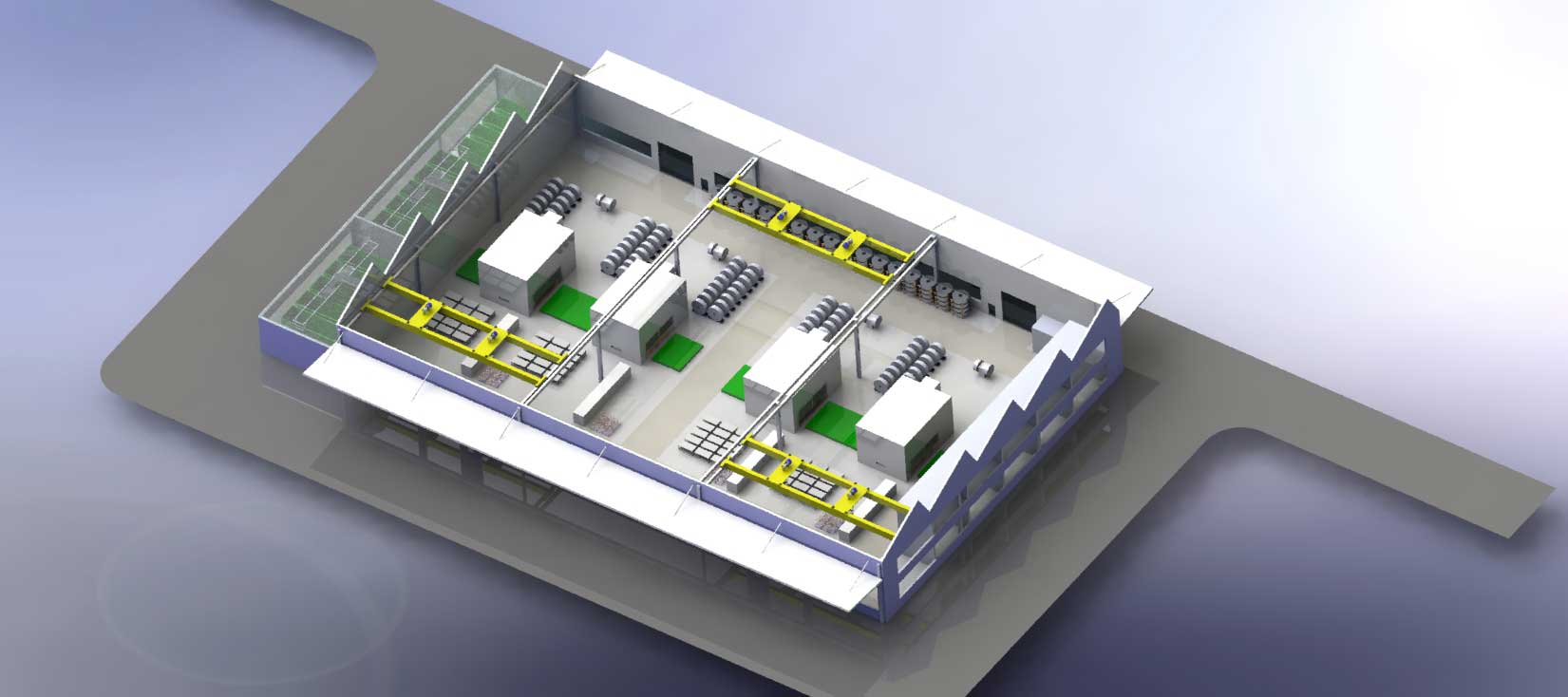

The Karlsruhe-based consultancy Integrated Logistics Systems (ILS) has taken on the role of general contractor for the overall planning of the production and logistics processes for the Hungarian site in Gyöngyös of the Munich-based Jungheinrich subsidiary Mias. As the company has announced, the plant located around 50 kilometers northeast of Budapest is considered the central production site for storage and retrieval machines (SRMs) for Europe and overseas...

ILS-MEDIA LIBRARY

DOWNLOADS

INTEGRATED LOGISTICS SYSTEMS

Postweg 51

D-76187 Karlsruhe

Germany

Tel: +49 721-97037-27

E-Mail: info@ilsystem.de

Factory Planning

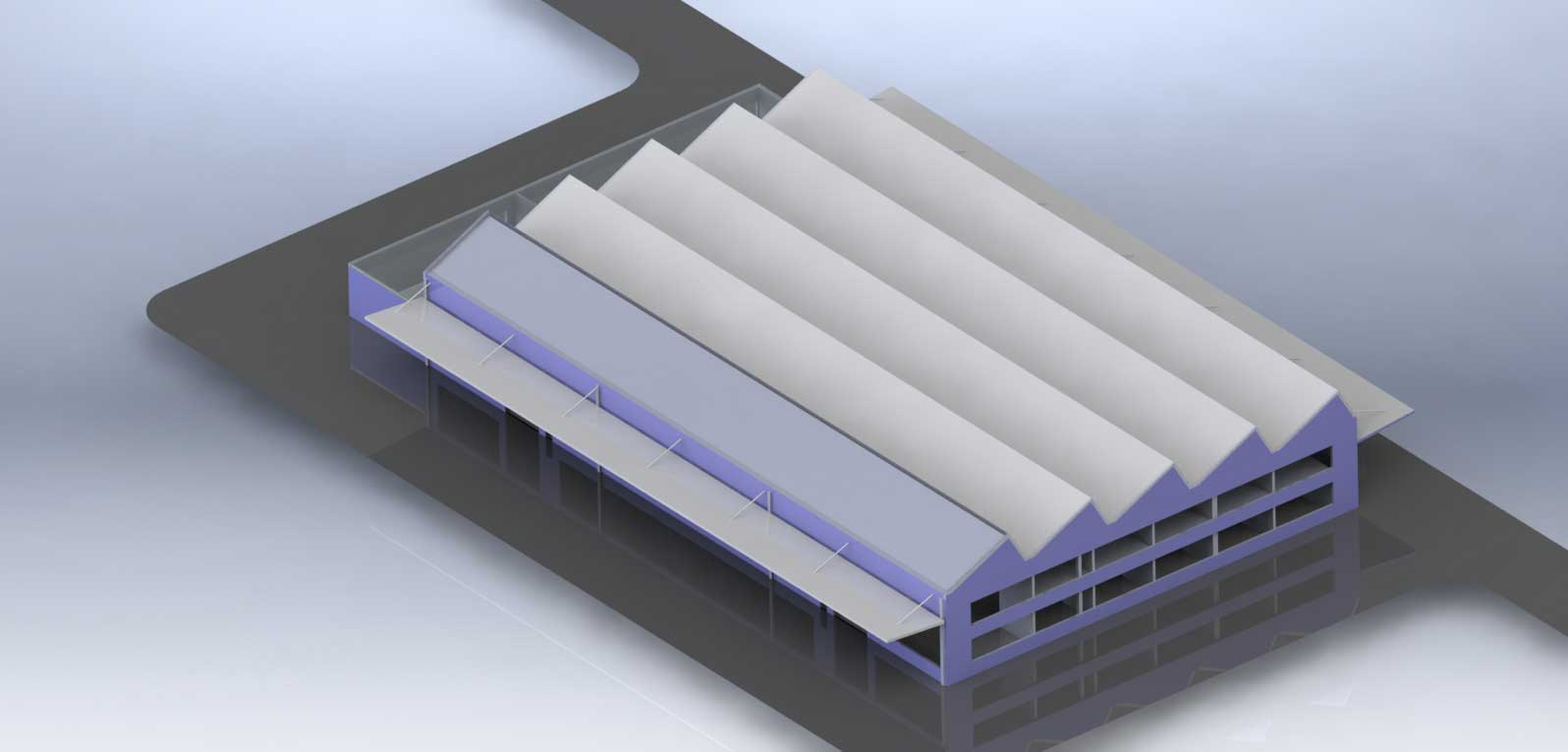

Holistic factory planning worldwide – over 20 years of experience

With over 20 years of experience in factory planning, we implement efficient production sites worldwide. Our expertise extends to Brazil, Hungary, Poland and Germany, among others.

With over 20 years of experience in factory planning, we implement efficient production sites worldwide. Our expertise extends to Brazil, Hungary, Poland and Germany, among others.

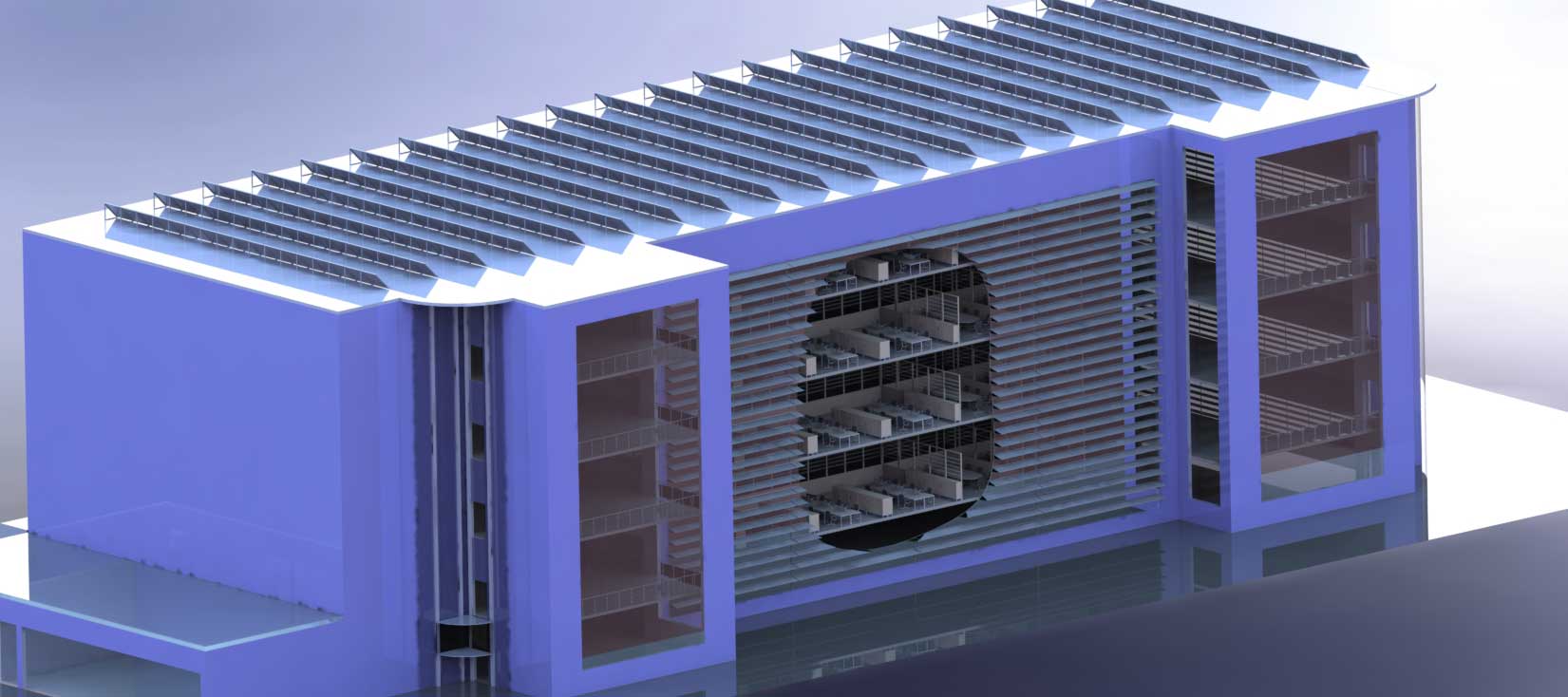

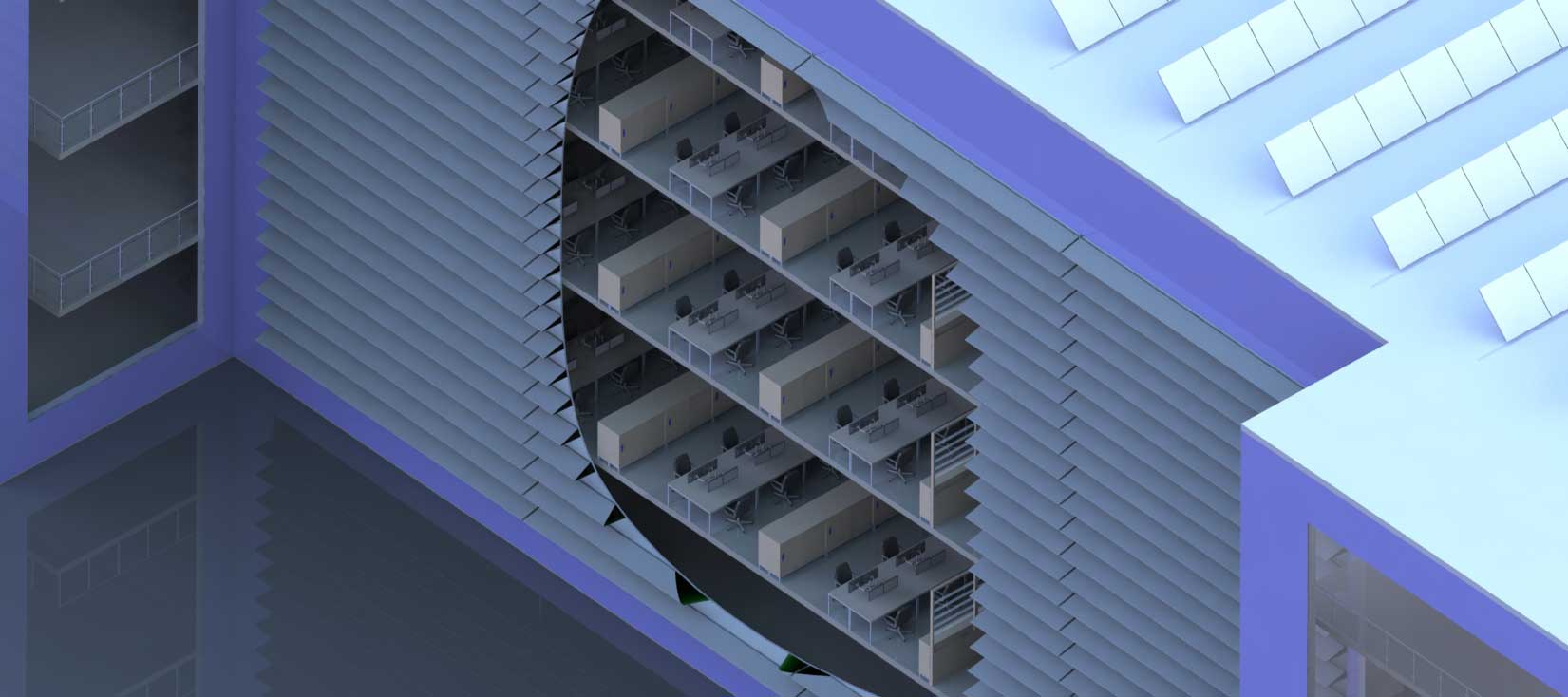

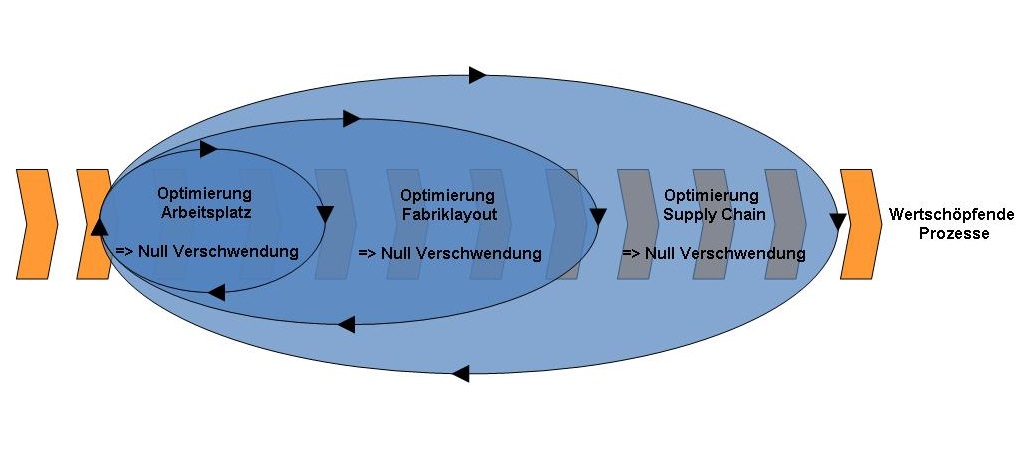

Our holistic planning approach includes project management from data collection and location determination to tendering and negotiations with suppliers. We oversee and take responsibility for deadlines and budgets to ensure that your projects are completed successfully. From implementation to commissioning, performance testing and handover to the customer, we accompany you professionally and reliably.

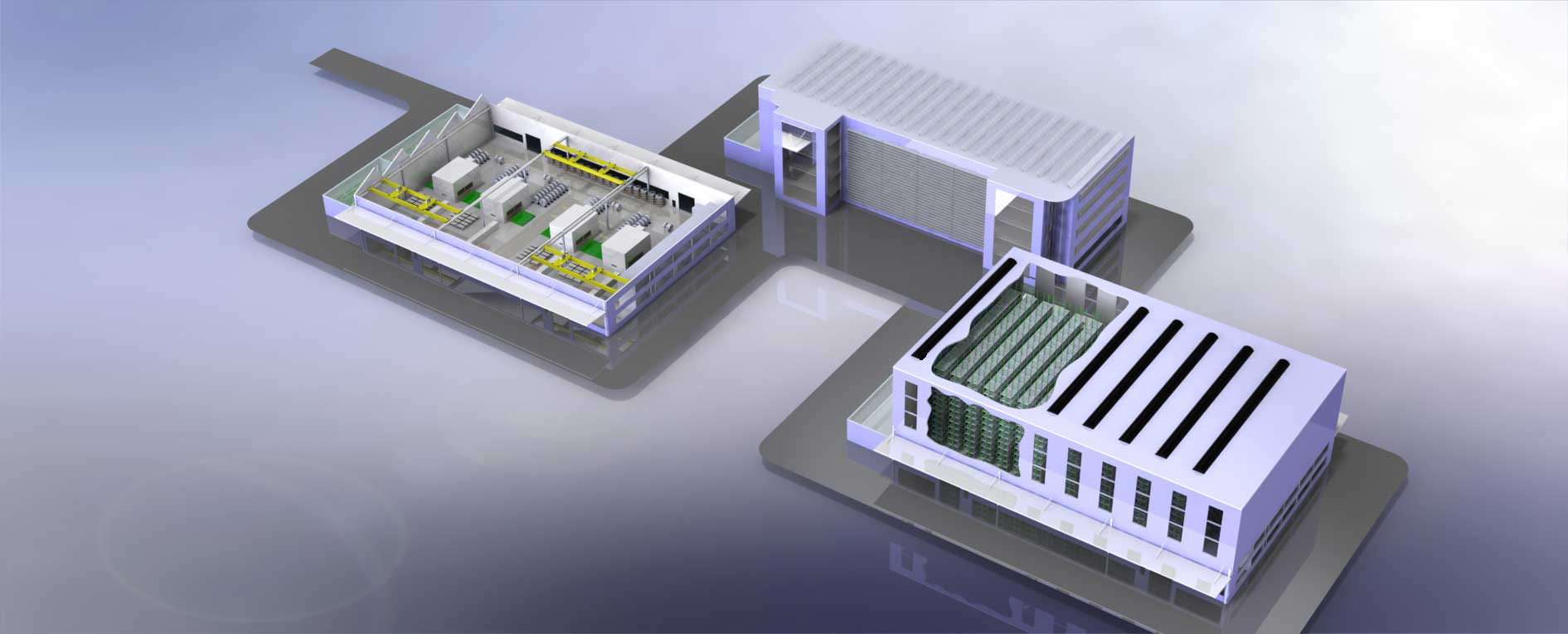

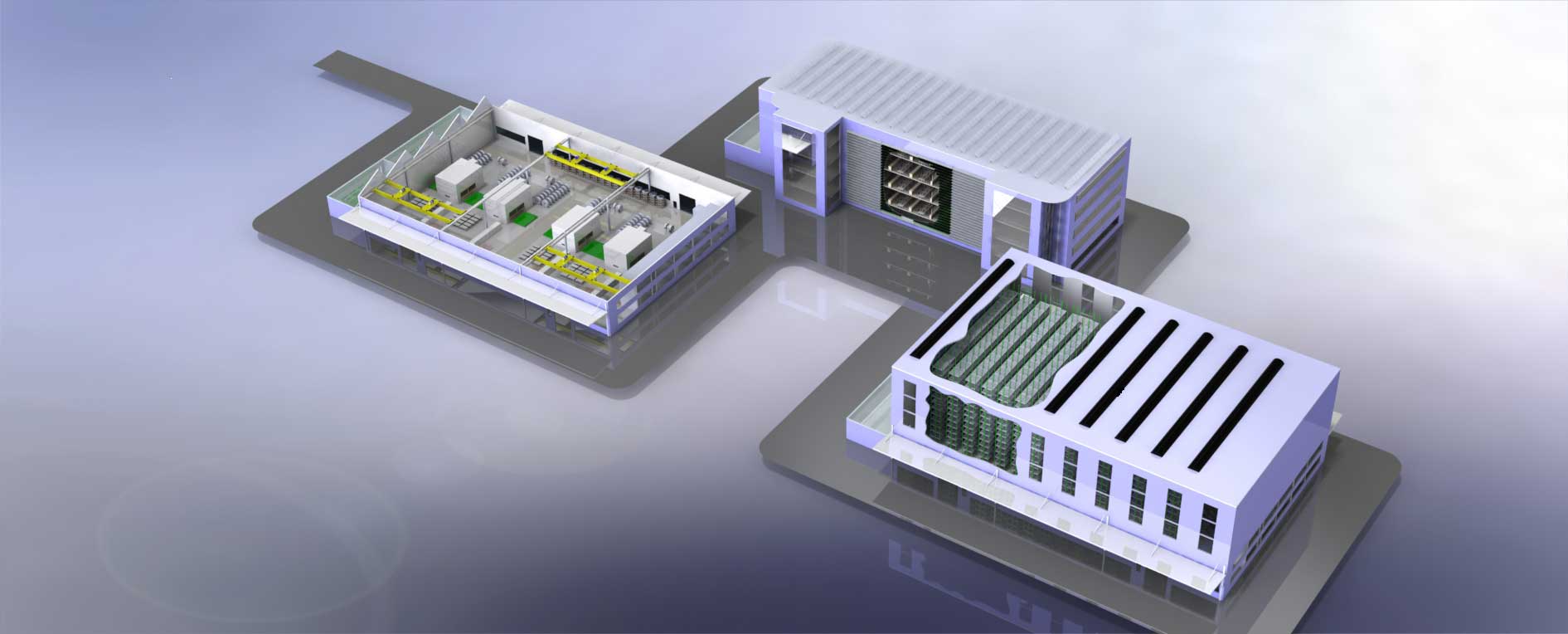

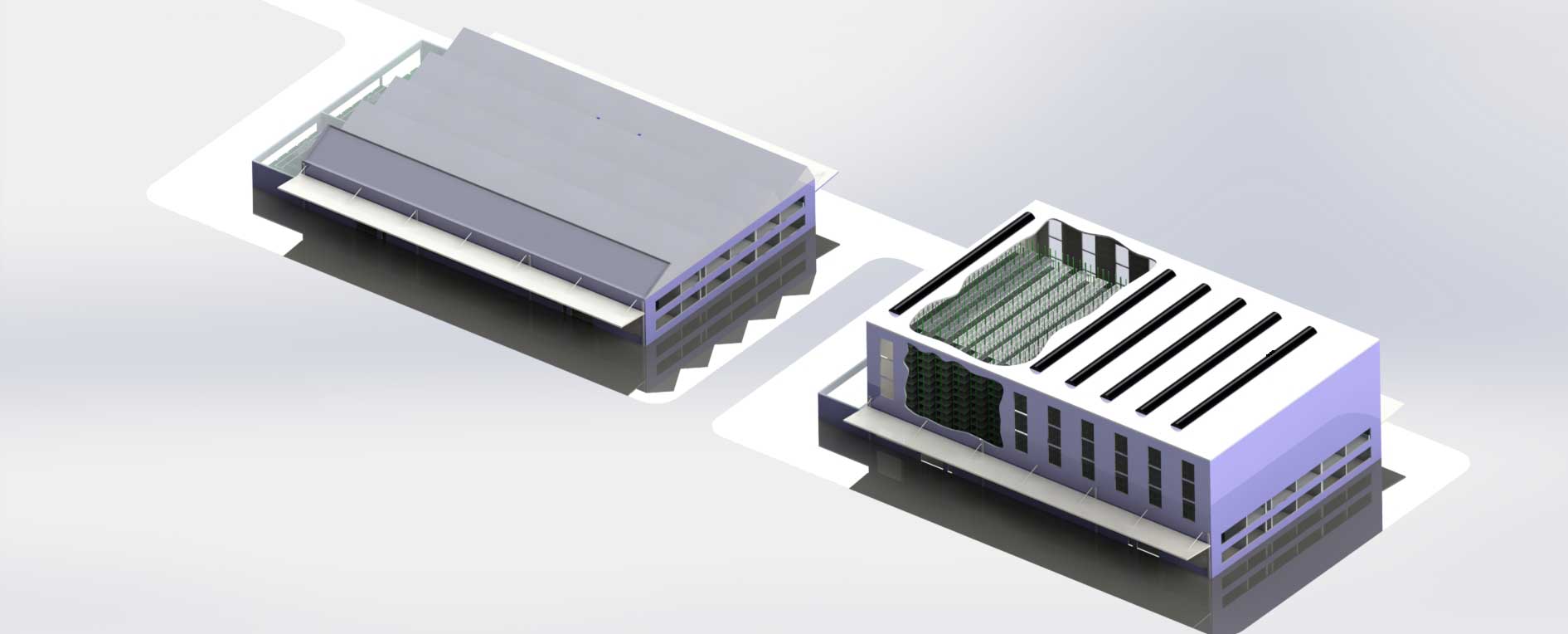

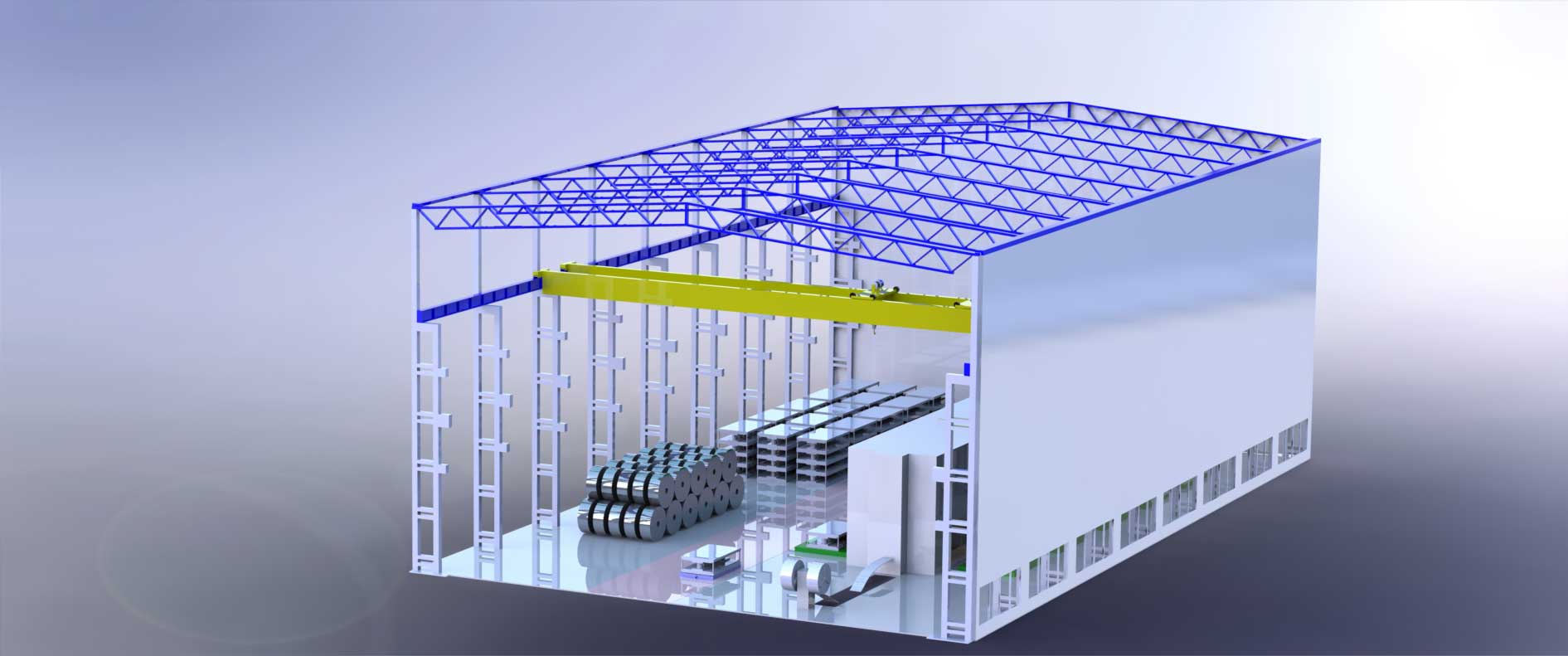

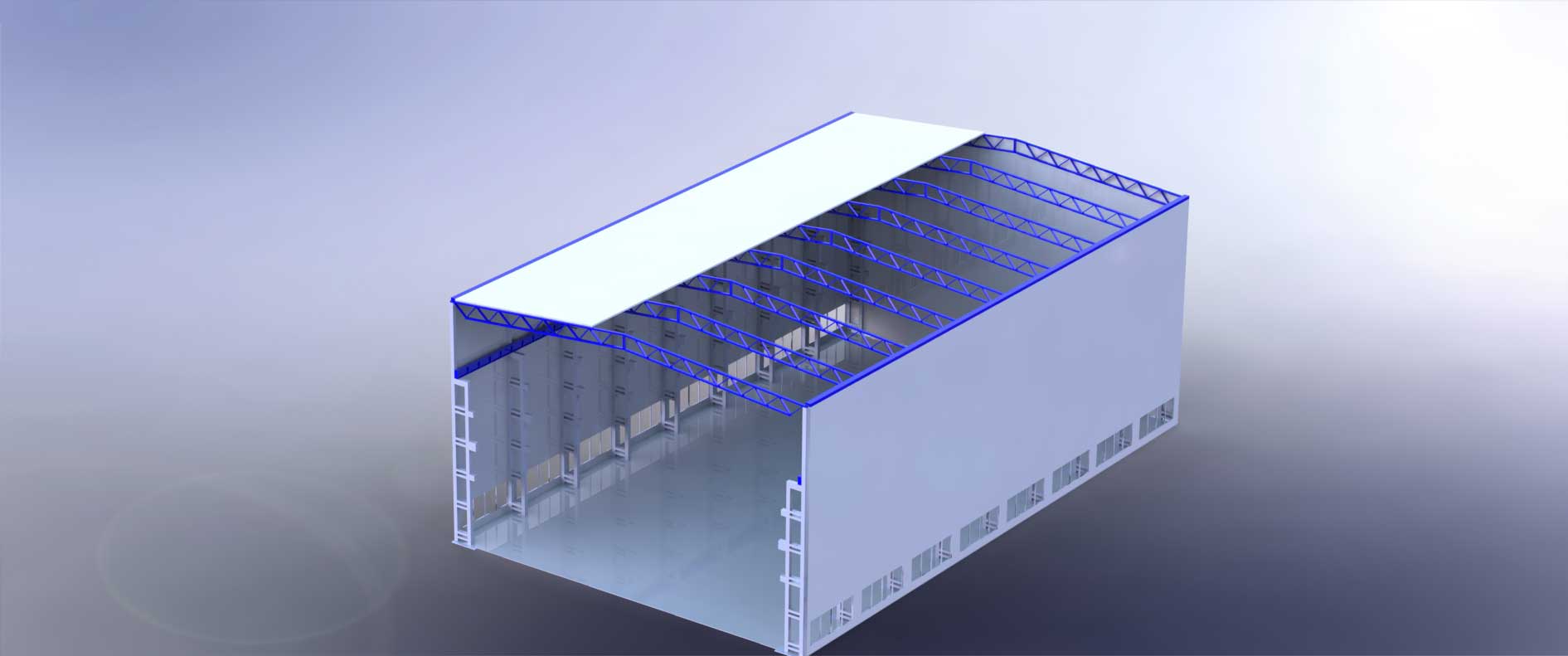

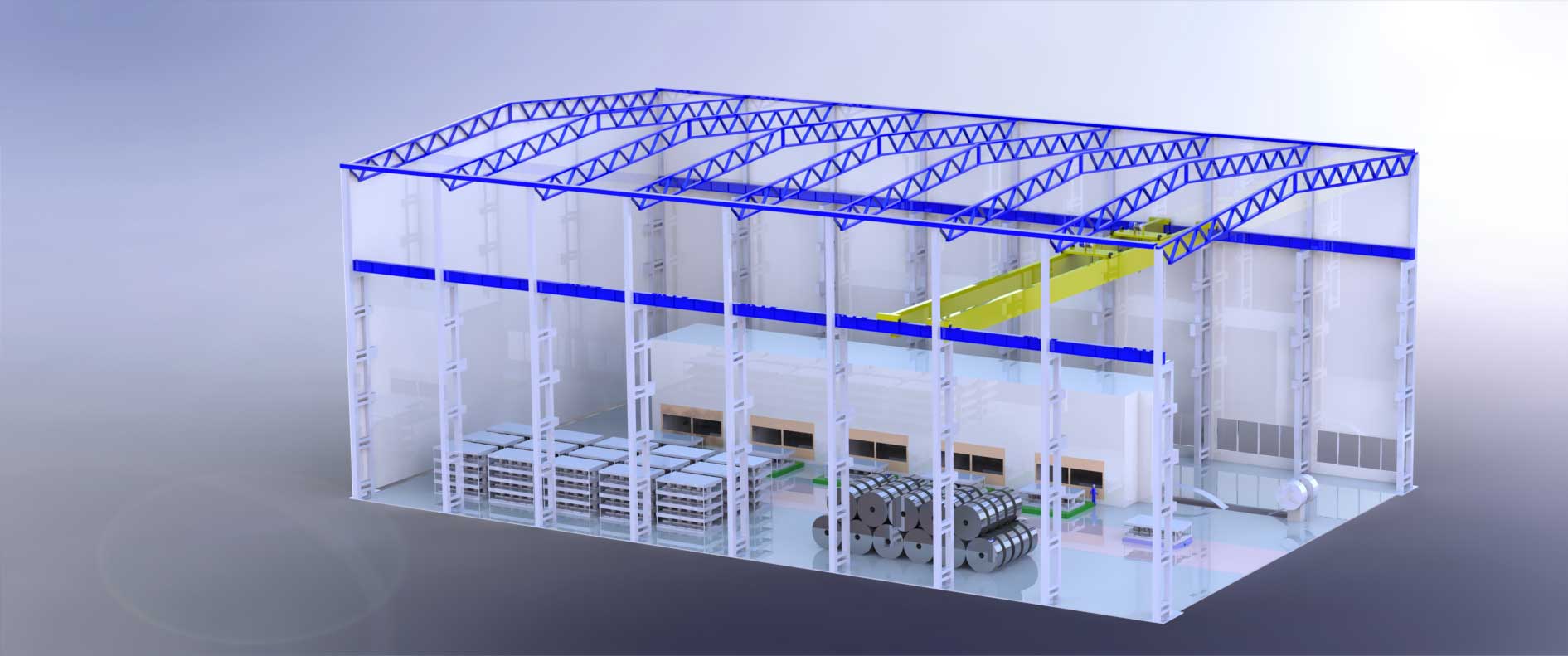

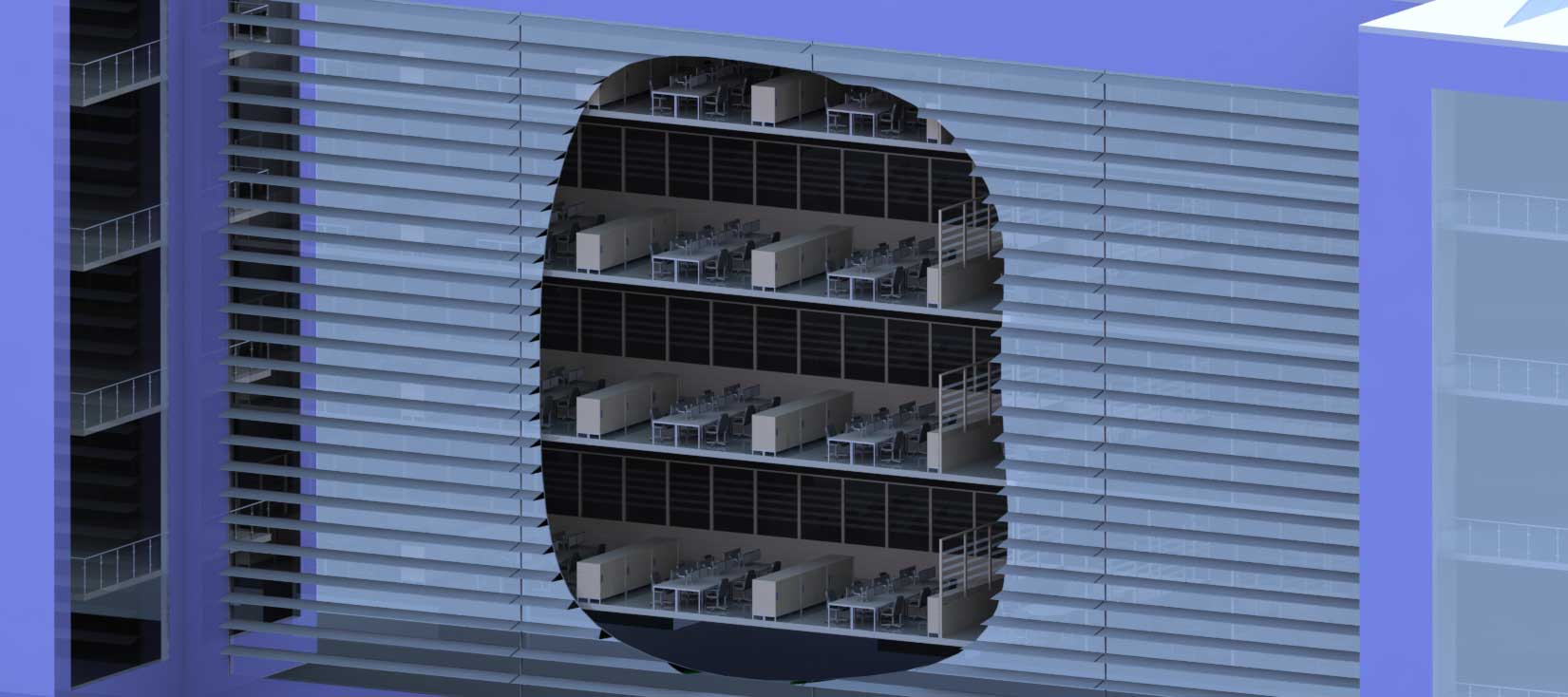

To ensure optimal planning, we use state-of-the-art 3D planning tools that allow us to simulate the processes and procedures. This allows us to identify potential bottlenecks or optimization opportunities at an early stage and act accordingly.

Successful project implementation – example MIAS Kft. Hungary:

A concrete example of our successful project work is the cooperation with the Jungheinrich subsidiary MIAS: As general contractor, ILSystems has taken over the comprehensive overplanning of the production and logistics processes at the Hungarian site in Gyöngyös. The plant, located about 50 kilometers northeast of Budapest, is considered the central production site for storage and retrieval machines (SRMs) for Europe and overseas.Thanks to our structured approach and precise planning, we were able to double the site's production capacity – clear proof of our contribution to increasing efficiency and securing the future of industrial production.

To the complete article in MM Maschinenmarkt („MIAS doubles production volume in Hunary“)

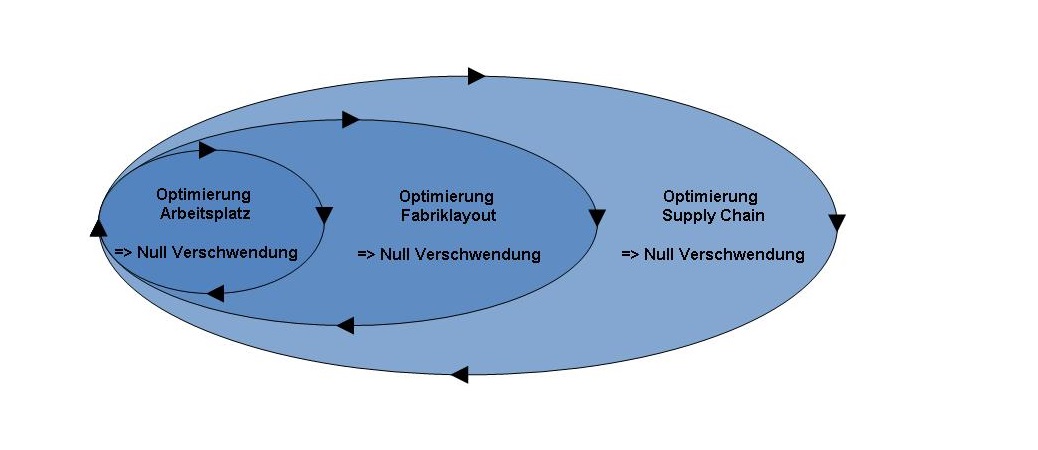

Supply Chain

Another focus of our work is the development of the supply chain. We support you in supplier management and monitor quality to ensure that your production operations run smoothly. In addition, we attach great importance to the documentation of the processes in order to ensure transparency and traceability.

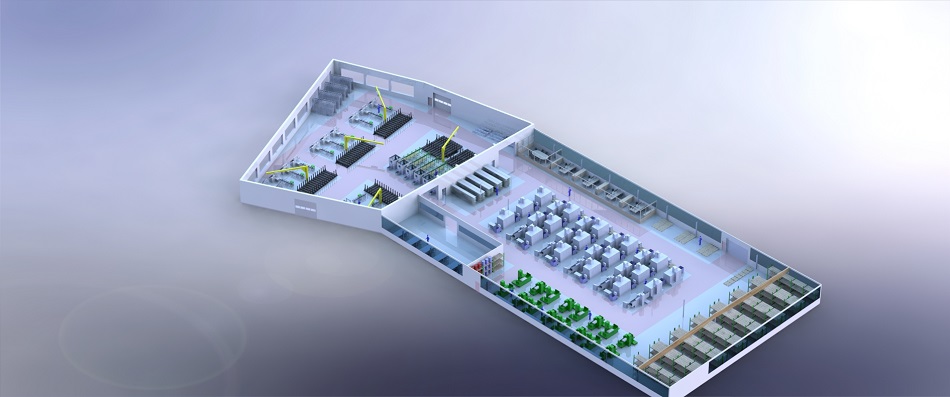

Smart Factory & Industry 4.0 – Your digital Production

We offer you tailor-made solutions for the smart factory of the future. With our expertise in the digital factory and networked production facilities, we are creating the basis for intelligent, efficient and scalable production. By integrating the latest technologies, we ensure that your factory is optimally positioned not only today, but also in the future.

Lean Manufacturing - Efficiency through lean processes

Our philosophy is based on Lean Manufacturing – a methodology that aims to reduce waste, continuously improve production processes and achieve sustainable process optimization. With innovative lean production approaches, we maximize your efficiency and at the same time contribute to reducing costs and resource consumption.

Industry 4.0 in Factory Planning – Digital Transition Now

By consistently implementing Industry 4.0 in factory planning, we are driving the digital transformation of production . We connect your machines and systems with cyber-physical systems so that you can access all relevant data in real time and optimize your production.

By consistently implementing Industry 4.0 in factory planning, we are driving the digital transformation of production . We connect your machines and systems with cyber-physical systems so that you can access all relevant data in real time and optimize your production.

Another decisive factor for sustainable production is factory layout planning. With intelligent factory layouts and well-thought-out concepts for production flow optimization, we ensure that your production lines are optimally arranged – for maximum efficiency and flexibility.

Automation in manufacturing is key to increasing productivity. We integrate advanced industrial robots and robotics into your production processes to automate repetitive tasks and relieve your employees. This leads to a significant increase in efficiency and better use of your resources.

Services

| Layout planning > | Process planning / IT processes > |

| Tender / tender evaluation > | Budget Management > |

| Bid evaluation / award recommendation > | Project management > |

| Price negotiation > | Needs assessment > |

| Welding equipment > | Strategy & Consulting > |

| Expert Services | |

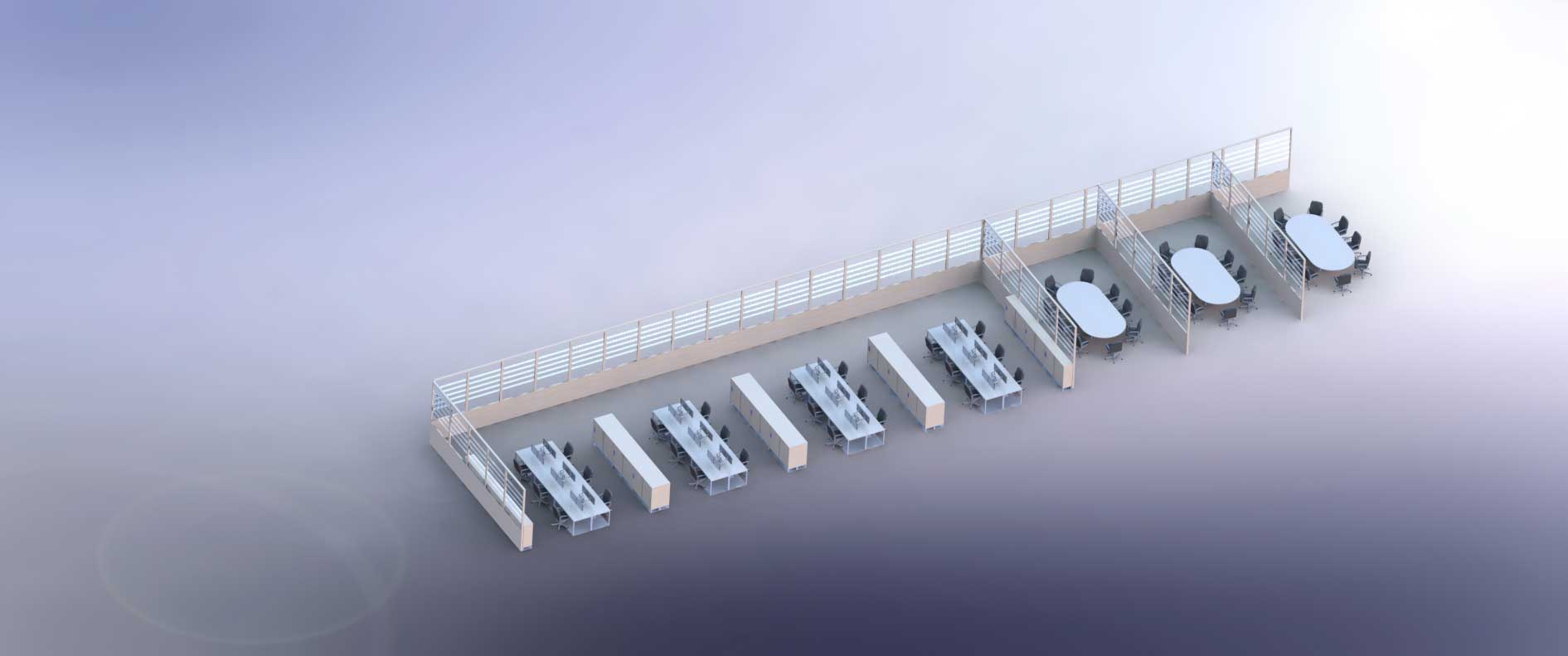

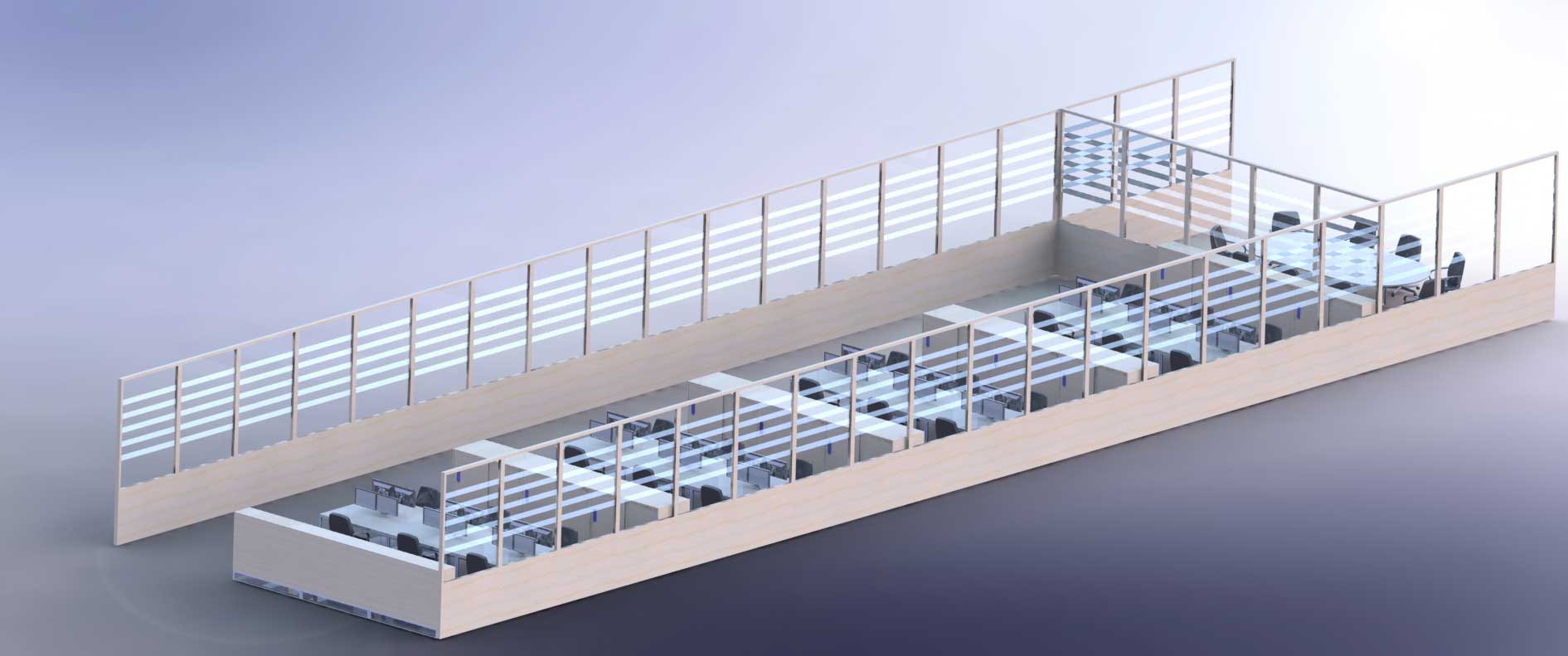

| Detailed planning of workstation > | Car assembly plant > |

| Sample workplace > | High bay warehouse > |

| Design and tender planning > | Logistics centers > |

| Evaluation of offers or trades > | Spare parts centers > |

| Price negotiation > | Engine plant / press shop > |

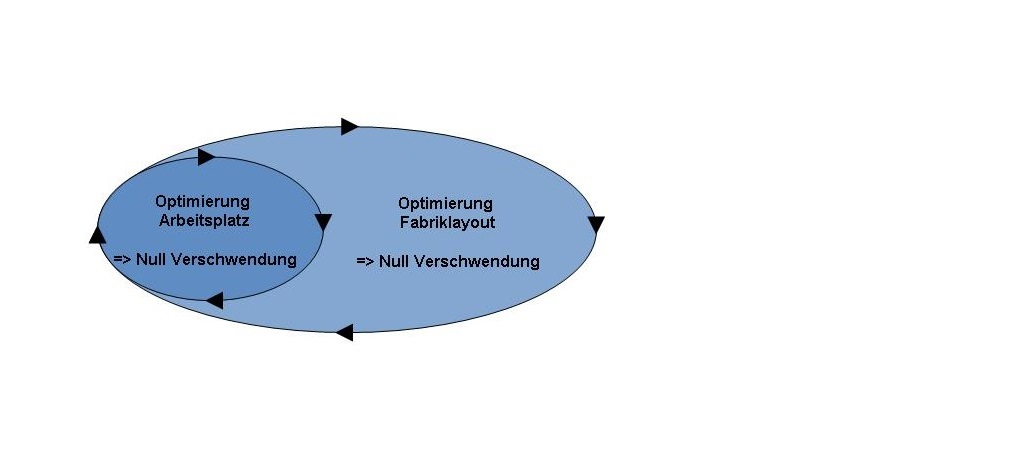

End-to-end planning approachMethods for efficient factory: |

|

|

|

| Image: Optimization workplace | Image: Optimization factory layout | Image: Optimization supply chain |

Site Development: